8 questions to ask before hiring a food and beverage construction company

The journey from initial project concept to an expanded or all-new food manufacturing facility is long, and it’s lined with complex decisions, evolving food safety regulations and shifting business drivers. To make the food and beverage construction project journey as smooth as possible, and arrive at a commercially successful outcome, start by familiarizing yourself with these eight mission-critical questions.

1. What should I look for in a food and beverage construction company?

What makes one architecture, engineering and construction (AEC) company different from another, and how can you conduct a thorough assessment when you’re under the pressure of an aggressive timeline?

There is no definitive right or wrong answer to this question. Every AEC company will bring unique value to the table, and your challenge is to recognize the company whose experience and capabilities fit most closely with your project’s particular needs and challenges. Our evaluation guide for finding the right AEC company for your food or beverage capital expansion project can help you navigate this challenge step by step.

Whatever approach you choose, remember this: technical expertise is only half the story. To identify the company that’s right for you, be sure to assess their cultural fit, as well.

Look for expertise in current and emerging food safety regulations.

You need a partner who understands the regulatory landscape impacting food manufacturing, including:

- The FDA’s Food Safety Modernization Act (FSMA)

- Good Manufacturing Practices (GMPs)

- 3-A sanitary standards

Beware, though: there’s a difference between AEC companies that offer a basic working knowledge of these regulations and those who deeply understand the principles behind them, how those principles apply to the real-world design and operation of a commercially successful food processing facility and what manufacturers can do to prepare for future changes in the regulatory landscape.

Look for AEC companies that include FDA-approved food safety authorities on their in-house team, and who demonstrate the expertise necessary to bring this regulatory perspective to your project from day one.

Search their track record for examples of successful food and beverage projects.

For most food manufacturers with a capital project on the horizon, speed-to-market is a critical driver of success. To meet your speed-to-market targets, you need an AEC company who has seen it all when it comes to food and beverage project delivery. That knowledge is like jet fuel, helping you move forward with both ready-made and rapidly tailored solutions to your most pressing problems.

When assessing an AEC company’s track record, look for two kinds of experience: vertical and horizontal.

- Vertical experience: Look for a history of solving problems and delivering projects specific to the food and beverage industry. These companies are intimately familiar with food safety regulations, vendor lead times for specific food manufacturing equipment, labor dynamics in particular regions and other key details. That knowledge enables them to take advantage of parallel workstreams, early package releases, staged construction, and other time-saving strategies as your project progresses.

- Horizontal experience: If applicable, look for companies that also offer transferable knowledge from other industries. This cross-pollination of expertise could give you a competitive advantage by opening the door to facility improvements or process optimizations that you didn’t know were possible. For example, manufacturers of cultivated meat may benefit from a project delivery team with extensive experience designing highly efficient, GMP-compliant facilities for the biotech industry.

Look for AEC companies that are focused on solving your problem (rather than selling their product).

The ideal AEC company will stand alongside you, taking a deep interest in the unique challenges you’re facing, the role of this capital project in meeting those challenges, and the business case behind it all. From that position of deep interest, an AEC company that’s oriented toward problem-solving (versus selling) will complement your expertise, not override it. They can add context to the challenges you’re facing and collaborate on solutions that will help you overcome those challenges.

At the same time, look for an AEC company who demonstrates a willingness to push back if they see another avenue for meeting your manufacturing goals, even if that avenue could impact their own interests. For example, they may suggest an operational improvement study which reveals that a simple process modification is all you need to meet your throughput goals, allowing you to postpone a significant capital expense.

Choose a team whose members like each other.

Meeting your project’s goals is important. But so is the journey to get there. Will that journey be pleasant… or miserable? Choosing a team that has obvious internal chemistry—a team that enjoys being in the interview room together, and draws you into that enjoyment—will determine the answer to that question.

Of course, enjoying the project matters, but reaching the finish line with a commercially successful project matters even more. When a team is cohesive and internally supportive, individuals on that team are empowered to ask tough questions, find unique solutions, and pull together toward a common goal—which generally means reaching that goal much faster, and with fewer headaches, than with a team incentivized by individual interests.

A single question can reveal it all

The challenge: A large-scale food manufacturing organization launched a complex capital expansion project worth hundreds of millions of dollars. Instead of a traditional RFP that would generate predictable responses from AEC companies, they wanted an approach that would help them identify creative thinkers and experienced problem-solvers more quickly.

To do that, they settled on a bold approach: their RFP asked a single question—“Why you?”

The solution: This question gave free range to responding AEC companies and taught an important lesson: sometimes the simplest inquiry can generate the most important result.

2. What pre-work should I do before engaging an AEC company on my food and beverage construction project?

Capital delivery projects are front-loaded with high-level decisions related to the project’s business case, its conditions of satisfaction, budgetary and scheduling constraints, and more. How many of these decisions should you have in place before moving ahead with your AEC company of choice?

In our opinion, you don’t need to burden yourself with all of this pre-planning before you engage your AEC partner. In fact, we’ve found a correlation between clients who work with us to define those high-level parameters and projects that finish on-time, on-budget, and in line with the business case. The right partner will get in the trenches and help you co-author your project’s vision—you don’t have to do it alone.

That said, there is one detail that you can define before engaging your AEC company, which will help you to right-size your level of commitment:

Calculate how much bandwidth you will have during project delivery.

If you’re like most engineering managers in charge of a capital delivery project, you’re juggling this responsibility alongside your everyday job. What does that mean in terms of your availability? Will you have the capacity to answer questions? Manage partnerships? Liaise between the design team and other service providers, including equipment vendors, trade partners and realtors?

Once you conduct an internal inventory of your own available resources and bandwidth, you’ll have a clearer idea of what you’ll need from your AEC company. Most engineering managers and other team leaders find it easiest to engage with a partner who has the experience, the industry relationships, and the know-how to autonomously manage a lot of the day-to-day communications and responsibilities of project management without creating a bottleneck. Defining your vision in these terms, and discussing that vision during your initial conversations with your AEC company, will position you for a more streamlined experience.

3. What contract method should I use for my food and beverage construction project?

Though the design-bid-build (DBB) method has retained popularity for decades, alternative approaches like engineering, procurement and construction management (EPCM) are gaining traction in the food and beverage manufacturing industry.

Understanding the drivers behind this shift from DBB to EPCM, and how those drivers might benefit your project, will help you select the best way forward.

Get to know the pros and cons of the design-bid-build project delivery method.

Pros:

- Historically, project teams have turned to this method because they believe it can help with cost control.

Cons:

- Partners are often selected according to the lowest bid, and each partner typically negotiates costs and profits independently (which incentivizes self-protection over shared rewards and responsibilities).

- Project roles are carved into individual silos, which can lead to numerous handoffs and elevate the risk of miscommunication and delivery delays.

Compare EPCM with the design-bid-build approach.

On complex projects that need to move fast, it helps to have all hands on deck from day one, which is the basis of EPCM.

Rather than navigating a handoff from a design-focused company to a construction-focused company, EPCM lays the foundation for full team integration, from initial concept phases through facility turnover. That means all subject matter experts are at the table from the start, including representatives from design, construction, automation, control systems and more. The result is a collaborative decision-making process that’s oriented towards a successful overall outcome, rather than a single entity’s interests.

With all hands on deck, an EPCM approach allows teams to take the long view in terms of constructability, site logistics, equipment selection, contracting, scheduling considerations and so much more. This holistic perspective unlocks the door to early design and cost certainty, which in turn frees project teams to take advantage of strategies such as prefabrication, preassembly, modularization and offsite fabrication (PPMOF). This can shave significant time from a project’s schedule while controlling costs and elevating quality.

Eliminating the bottleneck of long lead equipment

The challenge: When kicking off a capital project with a food manufacturing client whose commercial strategy depended on reaching the market before their competitors, we noticed a problem: they needed specialized filling and packaging equipment which could take up to 18 months to arrive.

The solution: We established an agreement to lock in the necessary manufacturing slots with long-lead equipment vendors immediately, even though we were still negotiating our overall contract with the client. Taking this step was only possible under the framework of EPCM, which brought together the necessary design, construction, and processing experts to make an early commitment and proceed with confidence.

4. What should I expect during a food and beverage project kick-off?

“Take your time… but hurry up.” This edict is often handed to AEC teams when they first meet with a food and beverage manufacturing client to launch a new capital project. And it’s the perfect way to describe what we believe is the most important element of project kick-off: the chartering phase.

An experienced food and beverage delivery team will begin the process with a project charter.

The chartering process is a mission-critical component of project kick-off. It’s a process designed to build consensus among organizational leaders, project team members, and other stakeholders around the project’s goals, its business case, and the ideal roadmap to success. Investing a small amount of time to develop a robust project charter at the onset of a project will save enormous time during later phases.

Key components of a robust project charter include (but aren’t limited to):

- Project purpose: Define the project’s “why.”

- Conditions of satisfaction (CoS): Get clear about what this project needs to accomplish.

- Ways of working together: Align on expectations around individual behavior, conflict resolution strategies, and overall team culture.

In addition to laying the foundation for some of these important decisions, chartering also provides the delivery team with an opportunity to address project-specific issues such as the potential for adverse weather (is construction scheduled during a period of potential hurricanes?), the unique constraints of a particular location (how far is the site from a major travel hub?) and more. Anticipating these issues well in advance positions you to navigate through them smoothly, or avoid them altogether.

Avoiding a product shortage while transitioning between facilities

The challenge: An owner planned to shut down an aging facility following an extensive renovation of another building. What made this tricky was the client’s product: it had a limited shelf life, which meant that the window to complete the renovation and scale up to full production was only eight months. If they overshot that window, they risked losing consumers as a result of unstocked shelves at the grocery store.

The solution: We confronted this challenge during the project chartering phase, which gave us the opportunity to establish a multi-faceted acceleration strategy in response. As design and construction progressed, all team members were pulling for the same result: project completion in under eight months. And thanks to that chartering experience and the solutions it generated, we succeeded.

5. Should I use the same AEC company for all stages of project delivery?

There are competing schools of thought when it comes to whether you should work with the same principal AEC partner from end to end or pivot to someone new at a certain stage in project development. It comes down to your initial selection, and what that means for your project.

Evaluate your current AEC company before moving into design and construction phases.

If you’ve selected an architecture, engineering and construction company with experience in the food and beverage industry and the resources to engineer and build a facility that meets your unique business needs, then you’re well-positioned to move forward with that company. You’ll benefit from a continuity of services, and from the depth of knowledge that your AEC company will have accumulated during your project’s early stages.

If, however, your AEC company is stronger in the early stages of project planning and not well-positioned to lead you through design and construction, you can put yourself at an advantage by shifting to a more suitable company. The successor can work with your previous AEC partner’s documentation to carry the project forward and help you streamline the delivery process with minimal friction or rework.

Design for the facility you need right now—and far into the future

The challenge: When a pet food processor wanted to build a large-scale greenfield facility, it wasn’t just about meeting today’s market demand. We worked with them to develop volume projections for the coming years, and determined that they would need to add a new production line to their facility every year for several years.

The solution: Because we were this client’s AEC partner from day one through final delivery, we were able to help them define their short- and far-term production needs, then build those needs into their facility design. That meant including slots for future equipment installations, additional footprint for rapid expansion, and a central utility building capable of supporting more than the initial operation.

6. What goes into a successful food and beverage facility design?

While you’re focused on your manufacturing process, your AEC team will work with you to consolidate the many complex design inputs that contribute to a resilient and commercially successful facility. The nature and type of those inputs will vary from project to project, but a few general considerations include:

Food safety and regulatory considerations

Your choice of AEC company will play a big role here. By partnering with a team that understands the complete regulatory landscape, you’ll get a compliant facility designed for end-to-end safety from day one. That’s the result when project teams carefully consider and integrate several critical factors in the most optimized, holistic approach possible, with flexibility for future adaptations. For example:

Segregation

Facility design plays a major role in mitigating the risk of allergen contamination (in the U.S., the leading cause of recalls is undeclared allergens).

Segregation is also the key to safely managing the boundary on either side of the “kill step,” preventing upstream raw ingredients from contaminating cooked products further downstream.

Material and personnel flow

Your facility’s design and layout will determine how materials, vehicles (such as forklifts) and people move within your operation, from the receiving area to the packaging line. Designing a safe flow that takes advantage of strategic adjacencies to enable efficiency and minimize travel time through the facility is key.

Planning for appropriate employee staging areas is also an important consideration. Where will your workforce enter the building, and how can you support their standard operating procedures (SOPs) with thoughtful design and infrastructure? That includes thinking through the gowning area—its placement in relation to the building’s secure entrance, its size, its layout and your ability to safely expand its capacity if you grow your workforce in the future.

Air handling

Designing an appropriate air handling approach, which includes filtration strategies and proper room layouts, is a key part of ensuring that clean manufacturing spaces stay clean. That means pressurizing certain rooms to prevent “dirty” air from flowing in, designing appropriate airlocks, and maintaining a safe distance between the air inlets in a production space and the air outlets on the facility’s roof.

Equipment selection and cleanability

Both your food processing equipment and the room in which it operates needs to be easy to clean and maintain.

That means taking time during the selection process to assess cleanability. How easy will it be to disassemble this piece of equipment and wash its component parts? Will an operator be able to fully drain its pipes and pumps between batches? Will it accommodate a CIP (clean in place) process, if that’s part of your strategy for hygienic design?

Food and beverage automation strategy

Do you plan to integrate automated technologies into your process, either today or in the future? Answering this question before designing your facility will allow you to avoid islands of automation and instead lay the groundwork for a harmonized, highly efficient whole based on a robust control systems integration strategy.

This answer will also impact the size of your labor force, which is a necessary design input in terms of right-sizing everything from your parking lots to your amenity spaces.

Food and beverage warehouse strategy

Defining your supply chain management strategy and understanding its implications in terms of available storage for raw materials will have a great impact on how you allocate and design certain areas of your facility.

For example, will you keep a large inventory of raw ingredients on-site to mitigate against potential supply disruptions? Or perhaps you’re brokering a third-party deal to enable off-site warehousing, which frees up valuable footprint in your own facility?

Food and beverage sustainability strategy

What is your organization’s vision for sustainable design, and how can you generate both business advantages and better climate outcomes through more efficient food manufacturing processes and equipment?

Food and beverage future expansion strategy

Understanding your organization’s overall master plan, and the role of this capital expansion project in meeting your long-term business objectives, will help you define a roadmap to future expansion.

A renovation project is an opportunity to correct the “sins of the past”

The challenge: When a large-scale food manufacturer wanted to integrate a new oven into one of their existing facilities, it sounded like a simple project—until the site study revealed that the replacement oven, which was larger than the original, would go right through the women’s gowning room.

The solution: What seemed like a problem soon became a golden opportunity. This facility, already several decades old, was built according to the best practices of the time—practices which were no longer best. In fact, both the men’s and women’s gowning rooms were located in the center of the building, which meant employees—and the contaminants they carried on their street clothes—had to traverse much of the building before they could change.

These problematic features of the old building were closely examined during the design phase. Working with the project owner, we developed a plan to harness the “new oven project” as a launchpad for significant safety upgrades.

This pre-planning positioned our client to meet their production needs year over year—and because we knew their facility inside and out, we were able to help them deliver each expansion project rapidly and seamlessly.

7. What are some of the common challenges during food and beverage construction and how can I avoid them?

If you’re leveraging integrated project delivery to accelerate capital expansion, then design and construction aren’t siloed activities—they overlap and contribute to each other, helping you move forward quickly by eliminating the rework and misunderstandings that can come with sequential handoffs. We like to consider the design inputs defined above and the construction-related factors explored below as part of the same continuum, each one influencing the rest and all of them playing an important role in streamlining project delivery.

With that in mind, you should approach the construction piece of your capital project with a few key considerations in mind, particularly if you’re undertaking a renovation or remodeling project inside a working facility.

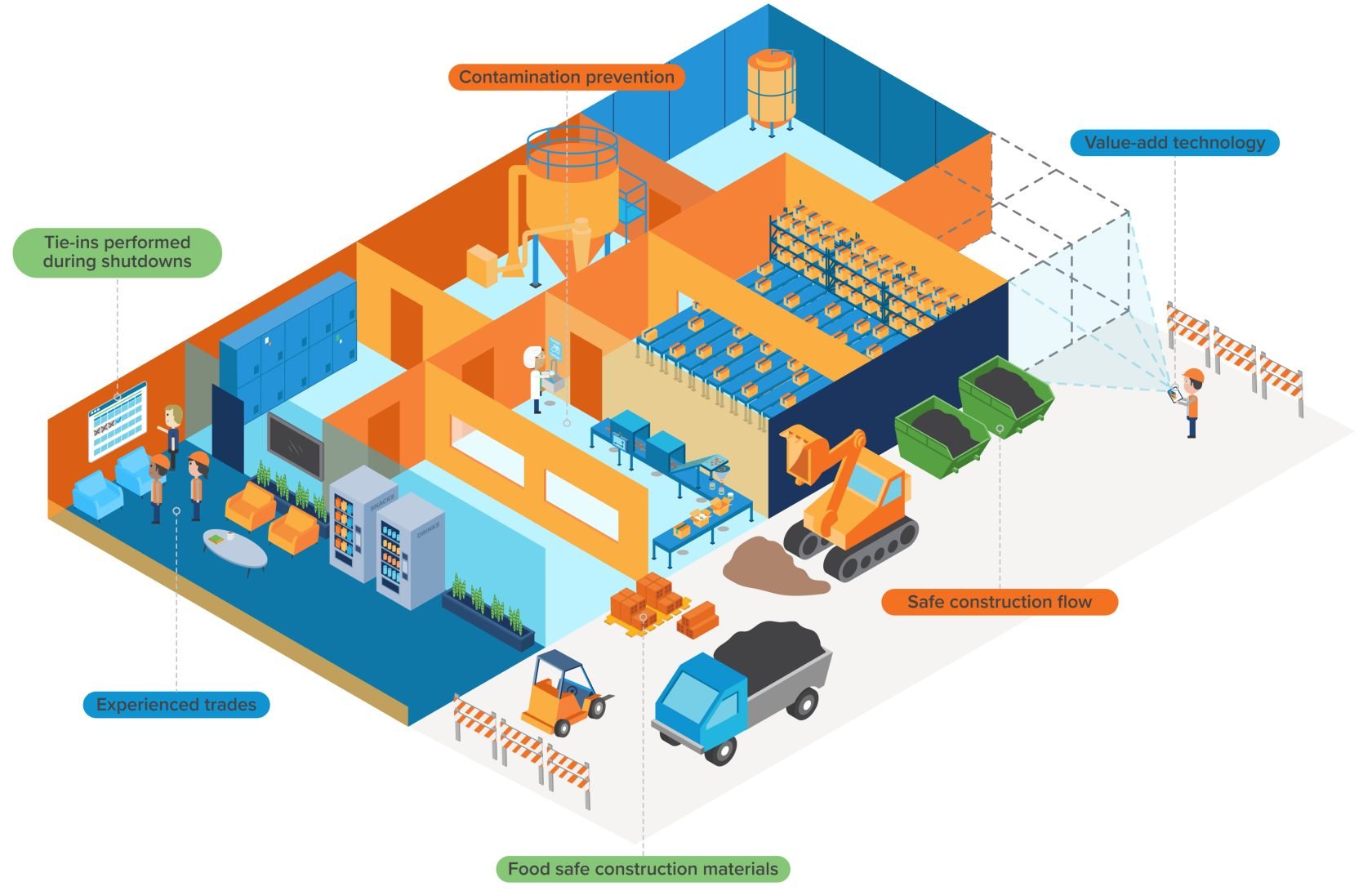

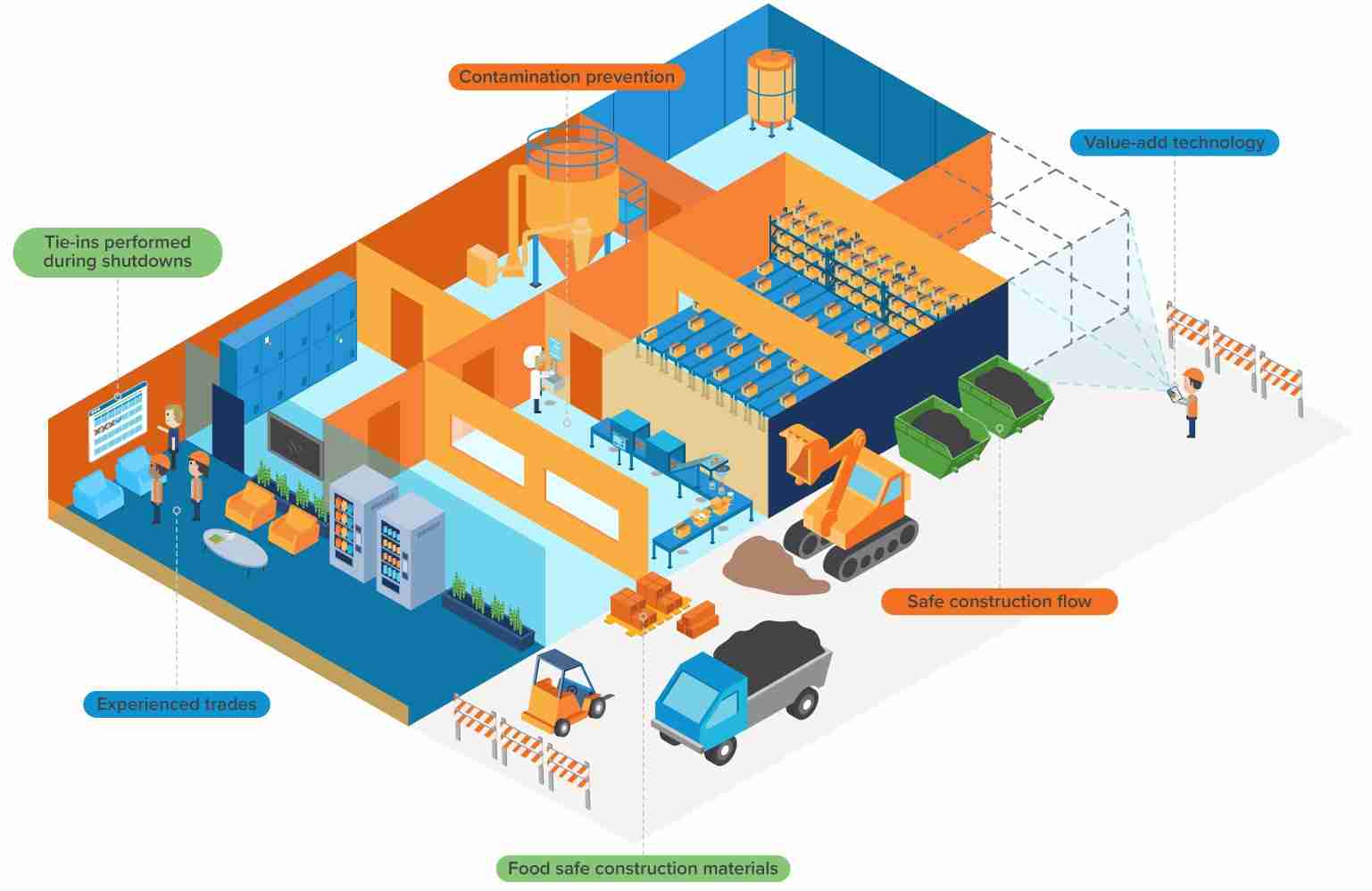

Plan appropriate construction tie-ins to avoid impacting the facility’s operation on food and beverage facility renovations.

If you’re an engineering manager overseeing the capital expansion of a working food or beverage manufacturing facility, having an experienced AEC partner who knows how to minimize the potential impact of construction flow on your operation will make your life significantly easier—and will help your organization continuously meet its throughput targets, even during construction.

Part of the solution is understanding when the facility will undergo a planned shutdown and skillfully planning construction activities so that all necessary tie-ins and other disruptive work is performed during those shutdowns.

Prioritize safety when operating a food manufacturing process and a construction zone side-by-side.

AEC companies experienced in the regulations and best practices governing safe food manufacturing will work closely with your EHS officer to plan their construction flow with safety and good hygienic practices in mind. They know the critical role that features like air pressurization play in preventing contamination, and they can work around these features, ensuring that facility operations and construction activities are strictly segregated.

In addition to safely managing the flow of construction materials and equipment into the job site, your AEC team will also have a strategy in place to manage all necessary demolitions and waste removal related to construction. This takes an experienced hand as well—for example, while removing a floor may be an everyday component of a “regular” commercial renovation, it requires special consideration in this context, where exposure to the soil could be a dangerous food safety hazard.

Select construction materials that comply with food safety requirements.

The risk of microbial growth is forever present in any food manufacturing environment. To reduce that risk, production spaces need to be highly cleanable, which means designing walls, floors and fixtures that can withstand frequent cleaning and won’t create concealed or hard-to-reach areas.

Material selection plays a big role here. Layering PVC over drywall, for example—a common practice in many construction projects—could create an opportunity for moisture to form behind the wall, inviting an undetected colony of mold which could potentially destroy an entire facility. Understanding these risks and applying a food manufacturing lens to the construction material selection process is key.

Include trades that are experienced in food and beverage manufacturing.

A strong AEC company can help ensure that all trade partners involved in constructing your facility or expansion project bring an appropriate level of food- and beverage-related expertise to the table, eliminating potential “blind spots” which could lead to safety issues or missed opportunities for added value.

Use construction tools that will streamline project delivery.

Positioning yourself and your construction team to make the right decisions at the right time is the single best thing you can do to accelerate project outcomes. And to do that, you need to take advantage of the latest in construction technologies, particularly Virtual Design and Construction (VDC).

Working with an experienced AEC team, you can leverage VDC to walk through your new expansion or facility while still in the design phase, giving the whole team an opportunity to spot risks, eliminate bottlenecks, and optimize the entire design before a single shovel hits the ground.

How construction teams and manufacturers work together

The challenge: An owner required a renovation project in the center of a million-square-foot fully operational food manufacturing facility. The project involved complicated tie-ins, significant demolition, and the need to transport large pieces of equipment and construction materials through the operating facility—without causing any unplanned interruptions.

The solution: By working closely with the project owner to understand how their shifts operated, when and how they scheduled downtime for maintenance and cleaning and other key operational details, we were able to complete the renovation seamlessly while our client continuously met their throughput goals.

8. How can I get the most from my food and beverage capital investment over the long term?

The food and beverage industry is constantly evolving, along with the regulations and technologies behind it. Your capital assets should evolve, too. That’s how you ensure long-term commercial success: by planning for flexibility and future expandability, and continually reassessing your operation to find opportunities for optimization and efficiency.

Focus on continuous improvement and optimization.

Never stop scanning for opportunities to optimize your process. Consulting with experts in operational improvement can help you eliminate wasted activities or reduce variability by standardizing your processes.

From new fermentation techniques to 3D printing devices, the food manufacturing industry is continually innovating. To stay competitive, you may decide to strategically introduce select innovations into your facility—a step which will be easier if you’ve proactively designed your facility to accommodate such implementations.

Look to other industries for inspiration. The biopharma industry has mastered the art and science of leveraging real-time operational data to drive efficiencies in manufacturing. How does your data strategy compare? Working with an AEC company who offers cross-industry experience can help you answer that question and find unique, powerful ways to continuously drive commercial success through a robust food manufacturing data strategy.

Choose design and construction experts for your food and beverage manufacturing facility.

There are many ways to plan, design, build, and operate a food and beverage manufacturing facility. You can move forward on your next capital project without considering these eight questions, but you’d be stuck on hard mode, learning tough lessons along the way and paying for those lessons in time and money.

Why not make project delivery easier on yourself, your organization, and the people who will work inside your new facility by preparing for what lies ahead and getting all the necessary food and beverage capital delivery experts in place from day one?

When you’re ready to get started, let’s talk .