Proper facility layout and design can help reduce the risk of allergen contamination in a food manufacturing facility.

With the public’s growing awareness of food allergies, there is a greater interest in allergen-free food products. A walk through the health food aisle of any grocery store presents a myriad of gluten-free, soy-free, dairy-free and nut-free options. Food producers committed to making products that are safe and appealing to consumers need to prioritize food safety—especially when it comes to working with potential allergens in food manufacturing.

Take a company that makes candy and peanut butter cookies in the same facility. The peanut dust in the air and on equipment poses a threat to making allergen-free candy. In this case, where it’s impossible to guarantee complete segregation and sanitation, the candy comes with the label warning we’ve all seen: “Processed in a facility that also processes nuts.” Unfortunately, while protecting consumers and the company from liability, this can be a barrier for many allergy-conscious consumers.

A food manufacturer looking to build a new facility or to build new process lines in an existing plant to produce allergen-free products needs to consider robust design and construction strategies to prevent allergen contamination or cross-contamination from other existing products. This will protect customers as well as the company’s reputation and bottom line. Given the complexity tied to constructing such a facility, a design and construction partner with food safety expertise can support facility owners in minimizing the risk of allergen contamination.

In this article, we describe what allergens are and how an engineering approach to facility and process design can help manage the risk of allergens in food manufacturing through layout, selection of equipment, the flow of materials and personnel, air handling, residues handling, warehousing, cleanability, and procedures.

What are food allergens?

Allergens are components of different foods that can cause an allergic reaction in some consumers. Allergens are usually proteins specific to certain foods that trigger an immune response and the amount needed to cause such allergic reaction varies from product to product.

An allergic reaction can range in severity from mild to severe, including some that are lethal. While most food allergens cause mild symptoms, a few can be dangerous, such as those that lead to the approximately 30,000 emergency room visits each year in the US for anaphylaxis. Food allergies can be prevented but not cured and, unlike pathogens, allergens are heat stable and cannot be eliminated with a kill step during production (e.g., cooking, pasteurization).

Allergen regulations

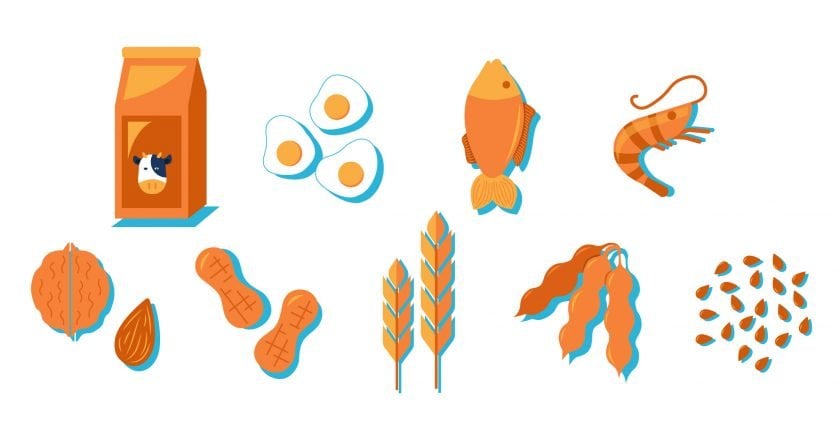

The Food and Drug Administration (FDA) and the US Department of Agriculture (USDA) regulate the production of foods in the USA. The FDA, based on the Food Allergen Labeling and Consumer Protection Act (FALCPA) of 2004, identified eight common allergenic foods, which lead to 90 percent of food allergic reactions. In April 2021, the Food Allergy Safety, Treatment, Education, and Research (FASTER) Act was signed into law, declaring sesame as the ninth food allergen.

The major food allergens recognized by the United States are:

- Milk

- Eggs

- Fish

- Shellfish

- Tree nuts

- Peanuts

- Wheat

- Soybeans

- Sesame

Foods containing any of the eight potential allergens identified in the FALCPA must bear a label identifying them. The FASTER Act will become effective on January 1, 2023, requiring the labeling of sesame as an allergen at that time. Many products are labeled claiming not to contain such allergens. Most food recalls in the United States arise from undeclared allergens.

In recent years, advances in science and risk assessment were taken into account and resulted in the Food Safety Modernization Act (FSMA), which was enacted in 2011. Its inception spurred a lot of processors to make changes in how they manufactured food. By regulation, every factory now has to comply with good manufacturing practices (GMP), and the owners can be personally liable for any infractions. One of the FSMA requirements is that all food manufacturers are inspected at least once a year to identify risks, including allergens. If an inspector has any concerns about a facility, they can undertake a full audit without notice.

Other jurisdictions have slightly different lists of allergenic foods than the FDA. For example, in addition to the eight allergens listed above, Health Canada’s list of priority allergens includes mustard, sesame seeds, and sulfites. The European Union adds celery, mustard, sesame seeds, sulfites and lupin to its list of allergenic foods.

Consumer awareness

Increased consumer awareness of food allergies has led to a demand for allergen-free products. This customer pressure has led some retailers, like Walmart and Costco, to insist that their suppliers get certified by any of the Global Food Safety Initiative (GFSI) programs, such as Safe Quality Food (SQF) and British Research Consortium (BRC). In all of the food-safety certifications, allergen management occupies an important role. This insistence on certification by big retailers has become an incredibly good driver for quality and safety in the food industry.

How good facility layout & design help control allergens in food manufacturing

FDA allergen labeling requirements only go so far to protect consumers from allergic reactions. FDA guidance insists that manufacturers adhere to GMP and not rely solely on labeling statements to protect the consumer. Each producer must find ways to avoid potential cross-contamination that can occur in a facility producing both allergen-containing foods and those meant to be allergen free.

In order to control allergens in food manufacturing, you need to consider many aspects of the process during the initial design phase of a new construction or retrofit:

- Material flow

- Segregation of process lines or areas

- Air handling

- Personnel movement, hygiene, and training

- Equipment selection

- Equipment and facility sanitation

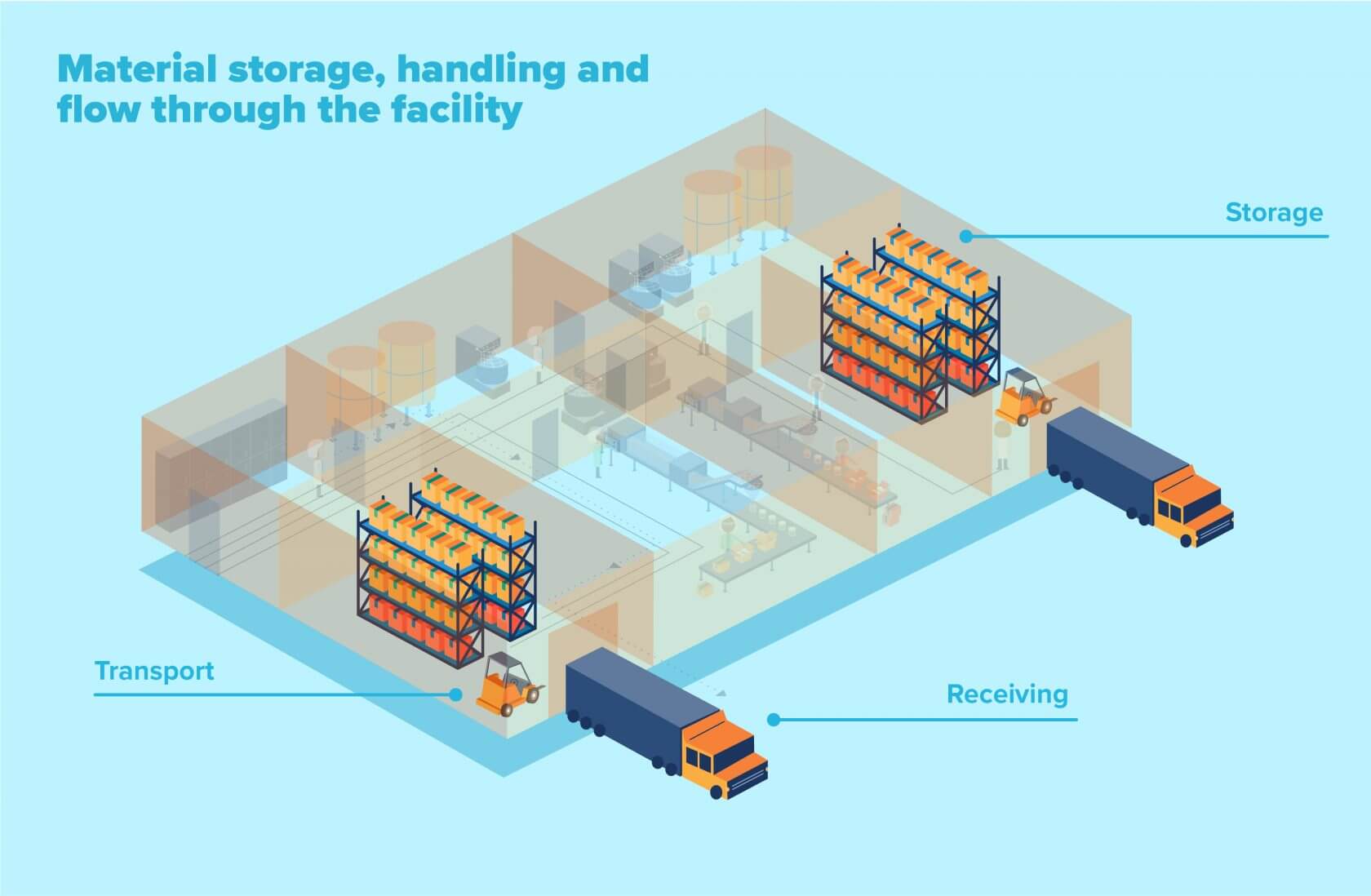

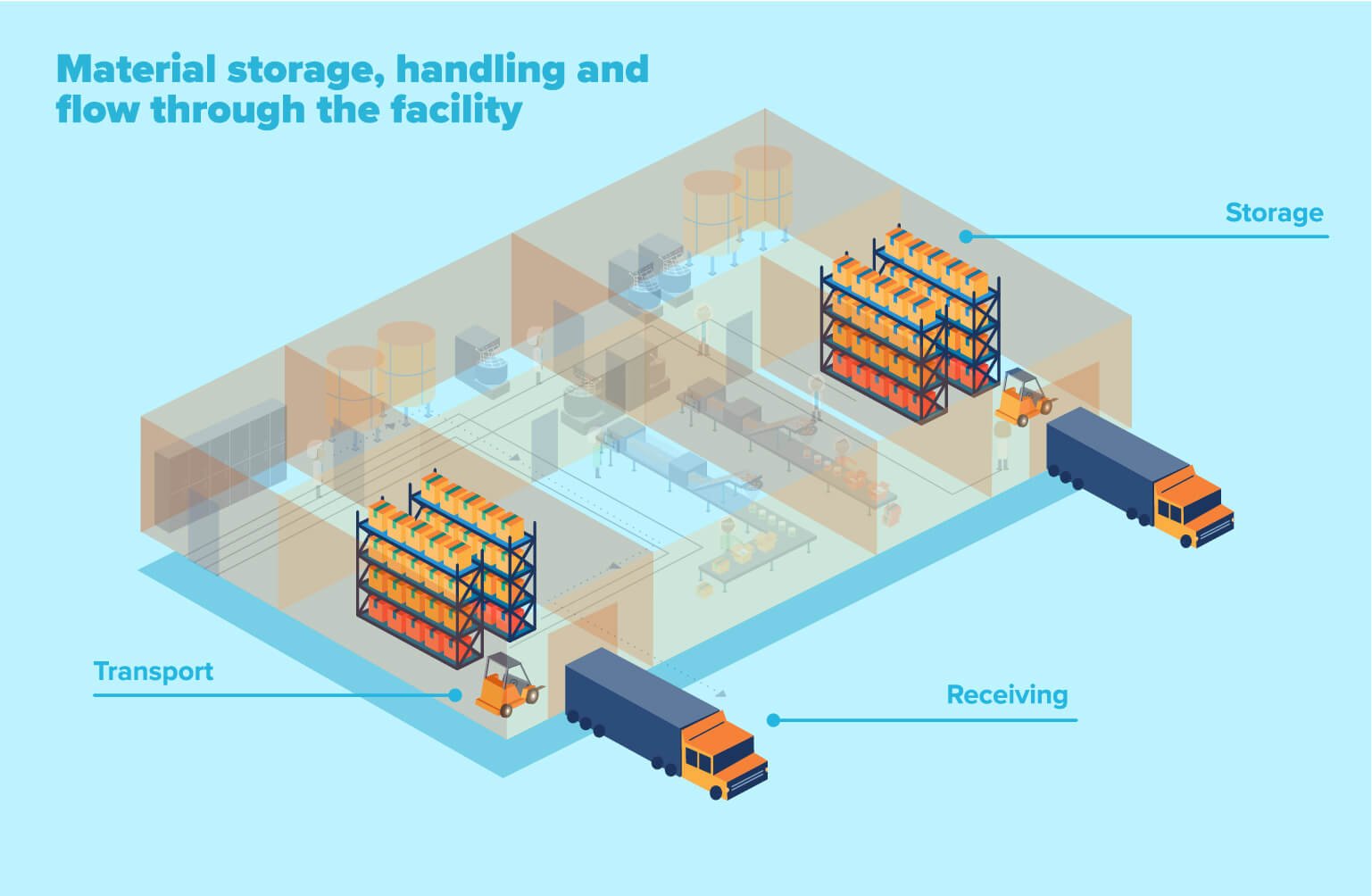

Material storage, handling, and flow through the facility

Food processors must avoid cross-contamination of allergens throughout the entire production process, which includes the way raw ingredients arrive at shipping and receiving, are stored, and are transported through a production facility. Therefore, these processes require careful planning to avoid potential problems.

Receiving requires the highest segregation of the entire process because raw ingredients are likely to be dirty or small spills may have happened during transportation. Think of receiving as the moat that will prevent allergens from breaching the walls of your fortress. Ideally, ingredients containing allergens should be received on a separate dock than allergen-free ingredients but that is not always feasible.

All ingredients must be properly and clearly identified and assessed to see if their packaging is intact. Allergen-containing raw materials are segregated and stored on lower racks so, if there is a spill, the ingredients will spill onto the floor and not on top of other ingredients. Exercise care to prevent allergens from becoming airborne.

The flow of materials from receiving through the factory needs to be carefully planned during design, especially if the warehouse is on the other side of the building. This minimizes the risk of cross-contamination of other ingredients and finished or intermediate products. This requires a careful layout of the corridors used to transport material. Possible measures that can be used are:

- Segregating corridors using walls, airlocks, and gates

- having separate forklifts and hand trucks for use in allergen-free and dirty areas

- air handling that provides higher air pressure in clean areas to prevent allergens from entering.

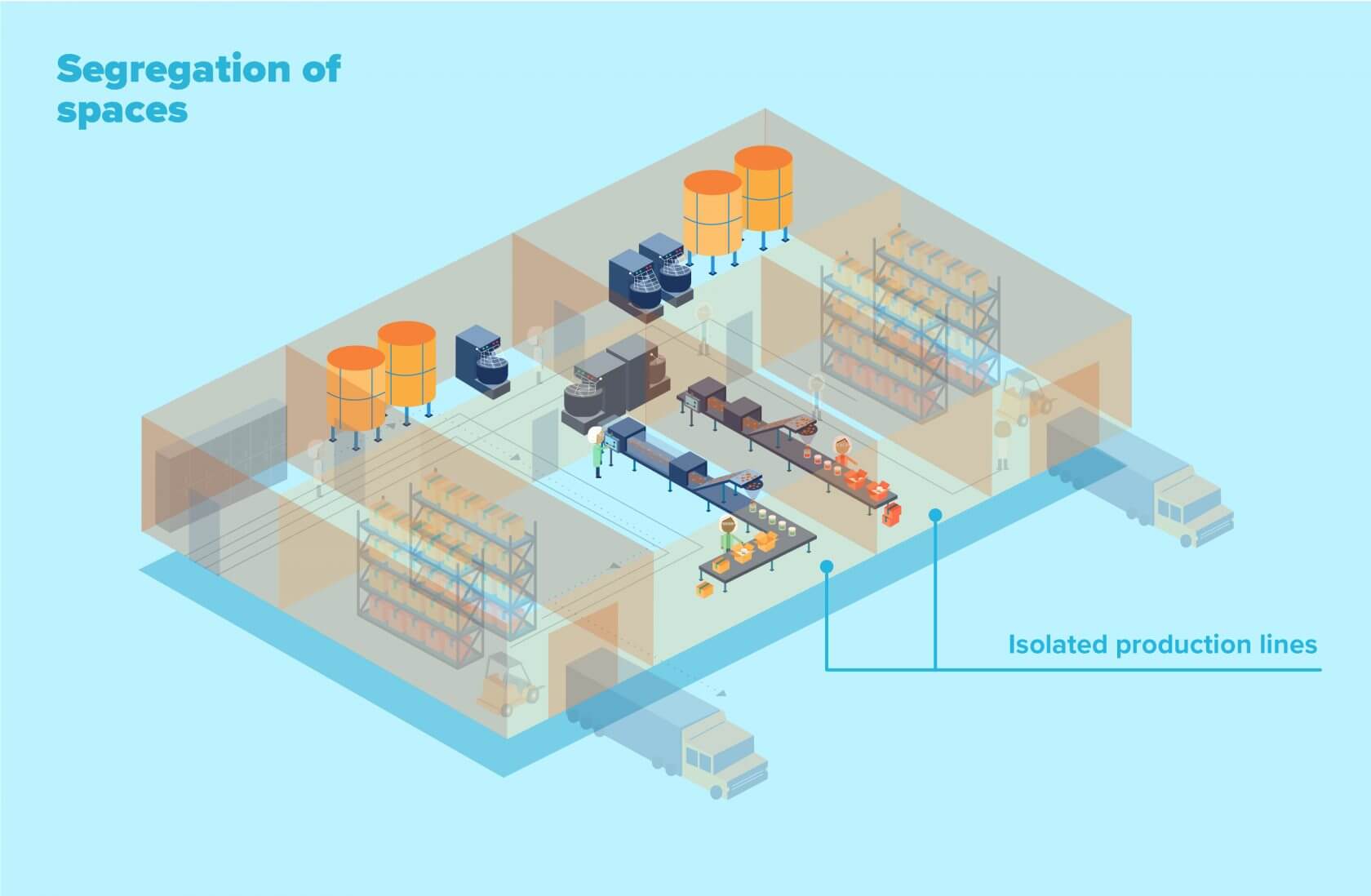

Segregation of spaces

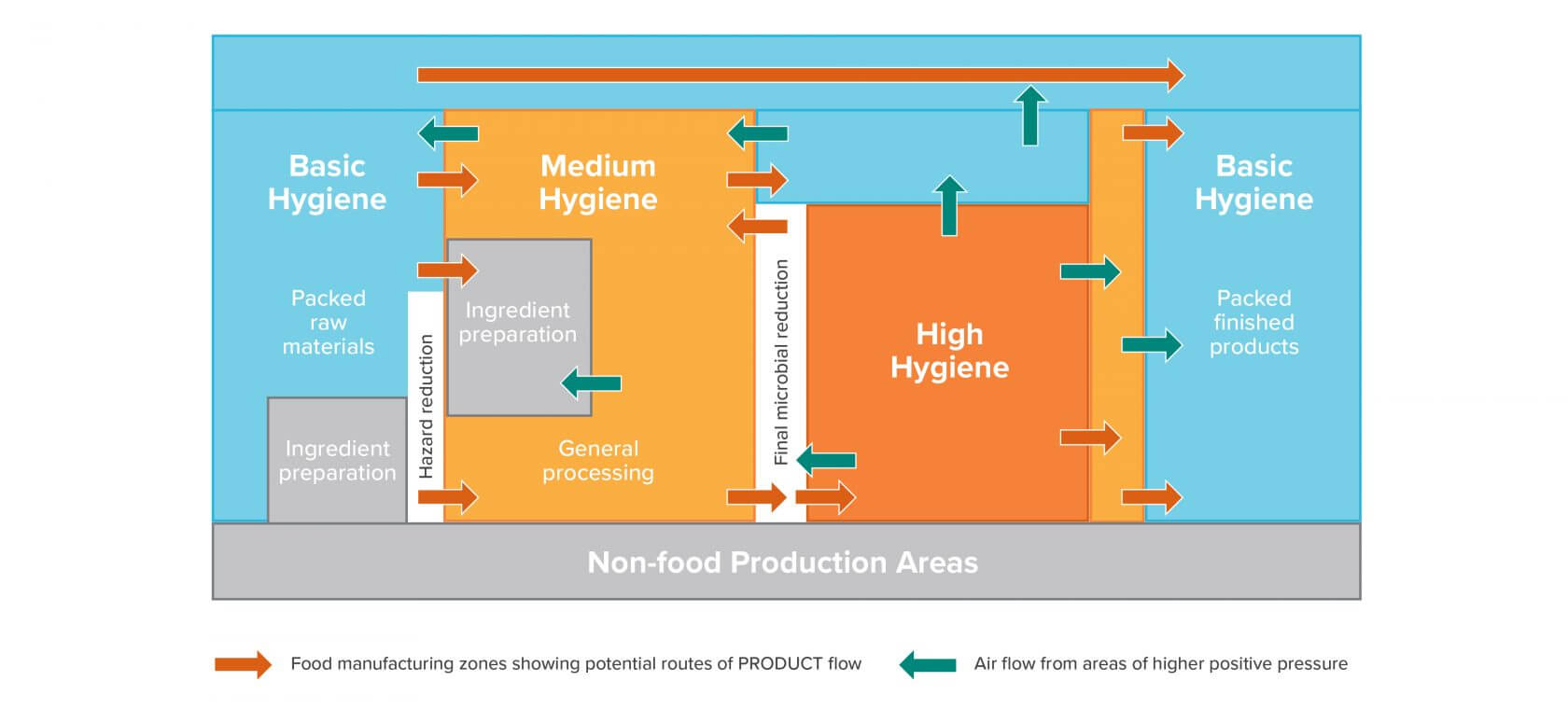

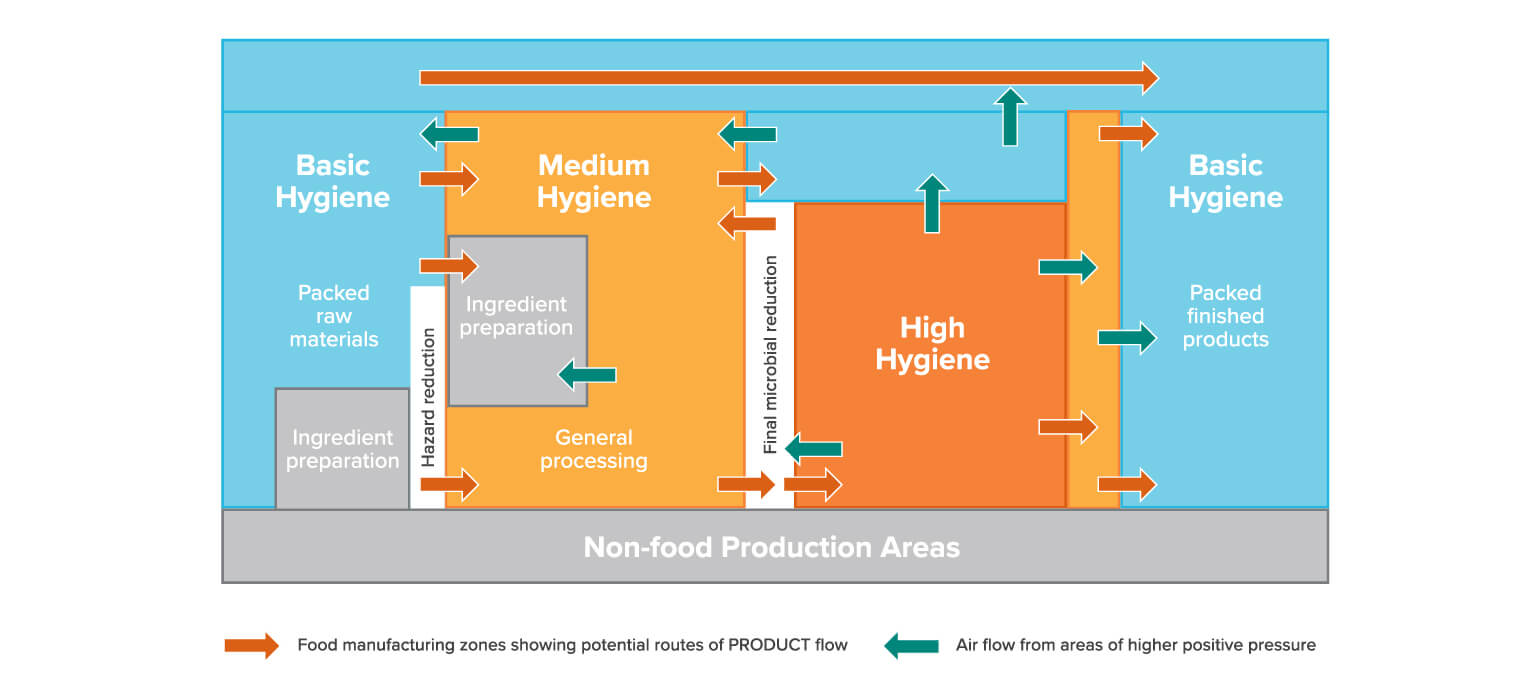

Facility layout impacts sanitation because it segregates the spaces assigned for clean (i.e., allergen-free) and dirty materials. Segregation—or isolation—is essential to prevent an allergen from contaminating a non-allergenic product when both are being produced in the same facility or even if one’s being transported through an allergen-free room.

Segregation can entail modifying equipment to isolate the process (e.g., having a small roof on top of a conveyor belt), isolating the equipment itself (e.g., having walls around the process line), or isolating an entire room so dust from other rooms cannot contaminate the inside. Segregation requires several steps, including physical walls, airlock rooms, and indirect walkways. All these efforts must take into account air handling and the way air flows so the higher pressure maintained in allergen-free areas causes clean air to flow out and prevents dirty air and dust from entering.

There are different levels of isolation. Complete isolation requires a dedicated facility to handle products that contain allergens. Larger manufacturers have the advantage of having multiple facilities or can build an addition onto an existing building. For example, they could have one facility that processes peanuts and keep other product lines completely segregated in a satellite building where only allergen-free products are made. This means they can also avoid a label warning.

This level of isolation may not be feasible for smaller companies. An alternative is to have isolated production lines within the same facility, following stringent sanitation to prevent cross-contamination. This allows a company to make products with multiple allergens on separate, isolated lines simultaneously. This is best done by having physical separation between different rooms that contain allergens.

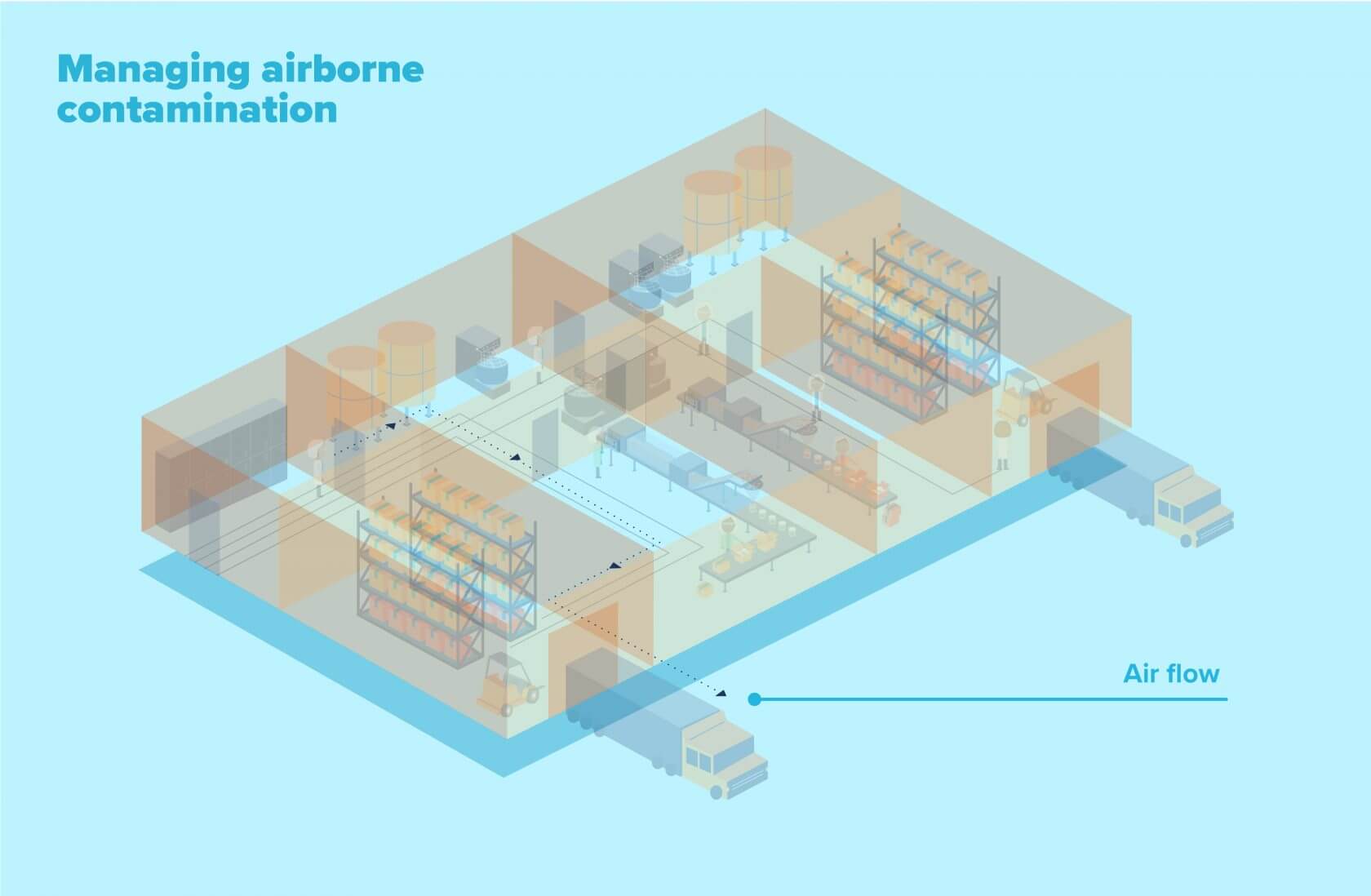

Managing airborne contamination

The way air flows through a facility is often overlooked in the food industry—but you need to think of air as an ingredient in each of your products. Because allergens can be airborne as dust or tiny particles and can travel long distances, proper air management in a factory is an important tool to prevent allergen cross-contamination. The design phase should include a focus on air conditioning and filtration to prevent the ingress of dust and to ensure the proper layout of rooms.

Allergen-free rooms need to be pressurized so air can only flow out of the room and allergen-containing (i.e., dirty) air cannot flow into the room. These higher-pressure rooms cascade towards less clean rooms, with warehouses and shipping and receiving having the lowest pressure. To maintain airflow and prevent disruptions when large gates are opened, use airlocks. Allergen management may require building a separate air handling system isolated from others in the facility.

One potential mistake is failing to maintain a safe distance between the air inlet and outlet on the roof. Determining wind patterns around your facility will help you prevent dirty air from being blown toward the clean air inlet and recirculating allergens.

This diagram shows how rooms can be positioned so that materials and air can flow through a facility to prevent cross-contamination. This is critical to managing allergens in food manufacturing.

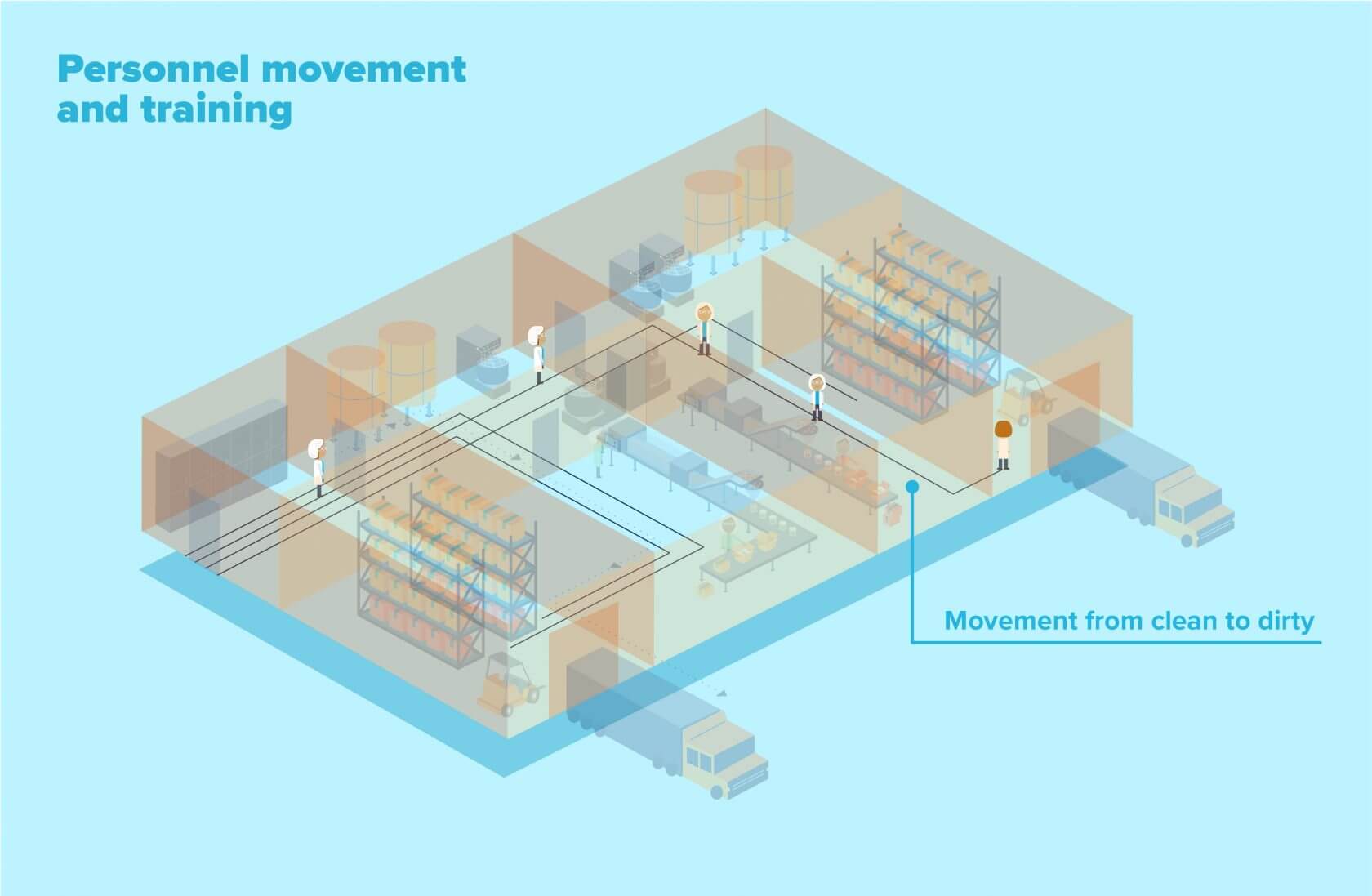

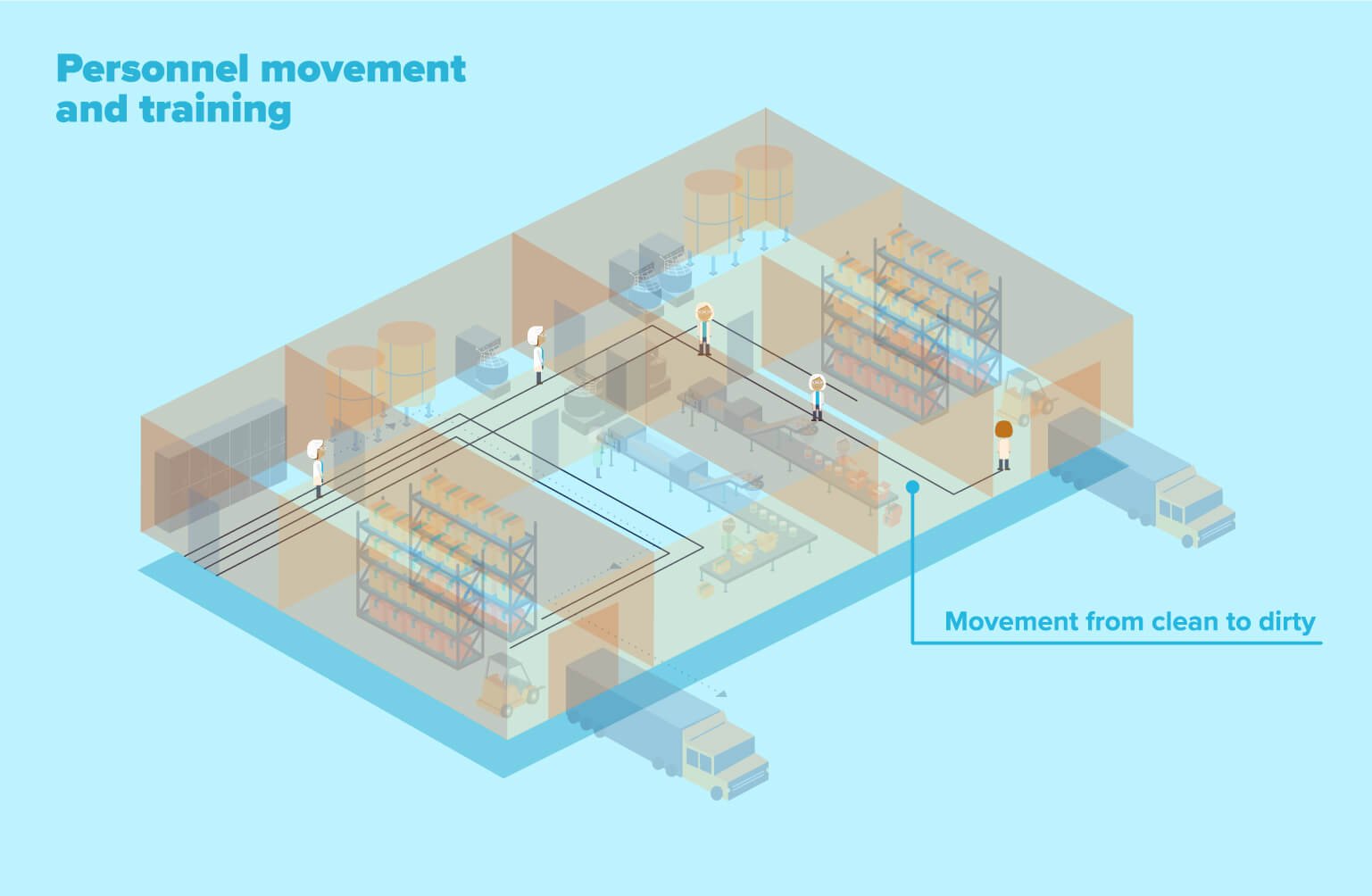

Personnel movement and training

Workers are a potential source of allergen contamination—on clothes, hair, and shoes—and they need to be well-trained in GMP, including simple things like cleaning their hands and footwear as well as the paths they should take to move from room to room. In extreme cases personnel also may need to be trained to avoid allergens in their lunches and in vending machines.

As with all materials, personnel should only move from clean areas to dirty areas and not be able to return. This includes movement from a dressing room into, for example, the packaging space. You may have to build a corridor so workers exit through a specific door and cannot walk towards the cleaner rooms. Depending on where they are going (e.g., to the raw room versus packaging), workers might have different colored shirts or hairnets so it is obvious when someone is out of place in an allergen-free room.

Movement is a special challenge for maintenance staff because they tend to work throughout a factory. The layout and design have to incorporate convenient and safe ways for them to move from clean to dirty areas to prevent contamination. For larger companies, maintenance staff may even have different sets of tools for clean and dirty rooms to avoid having to transport allergens from room to room.

The best way to avoid human error is to provide regular and continuous training to reinforce sanitary procedures. You can’t train your team once and expect them to retain all the procedures. A proactive, consistent approach to training is vital to managing allergens in food manufacturing.

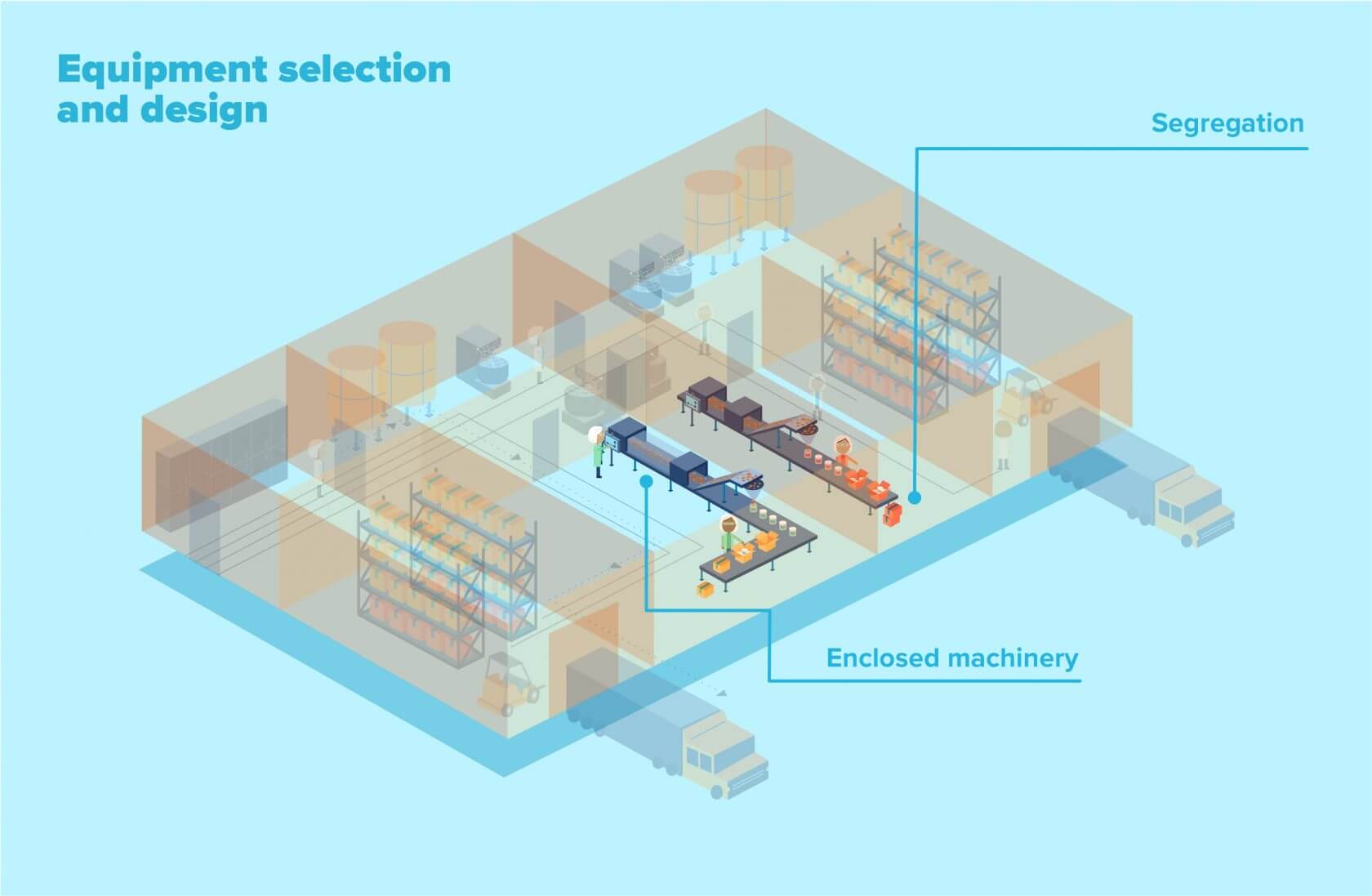

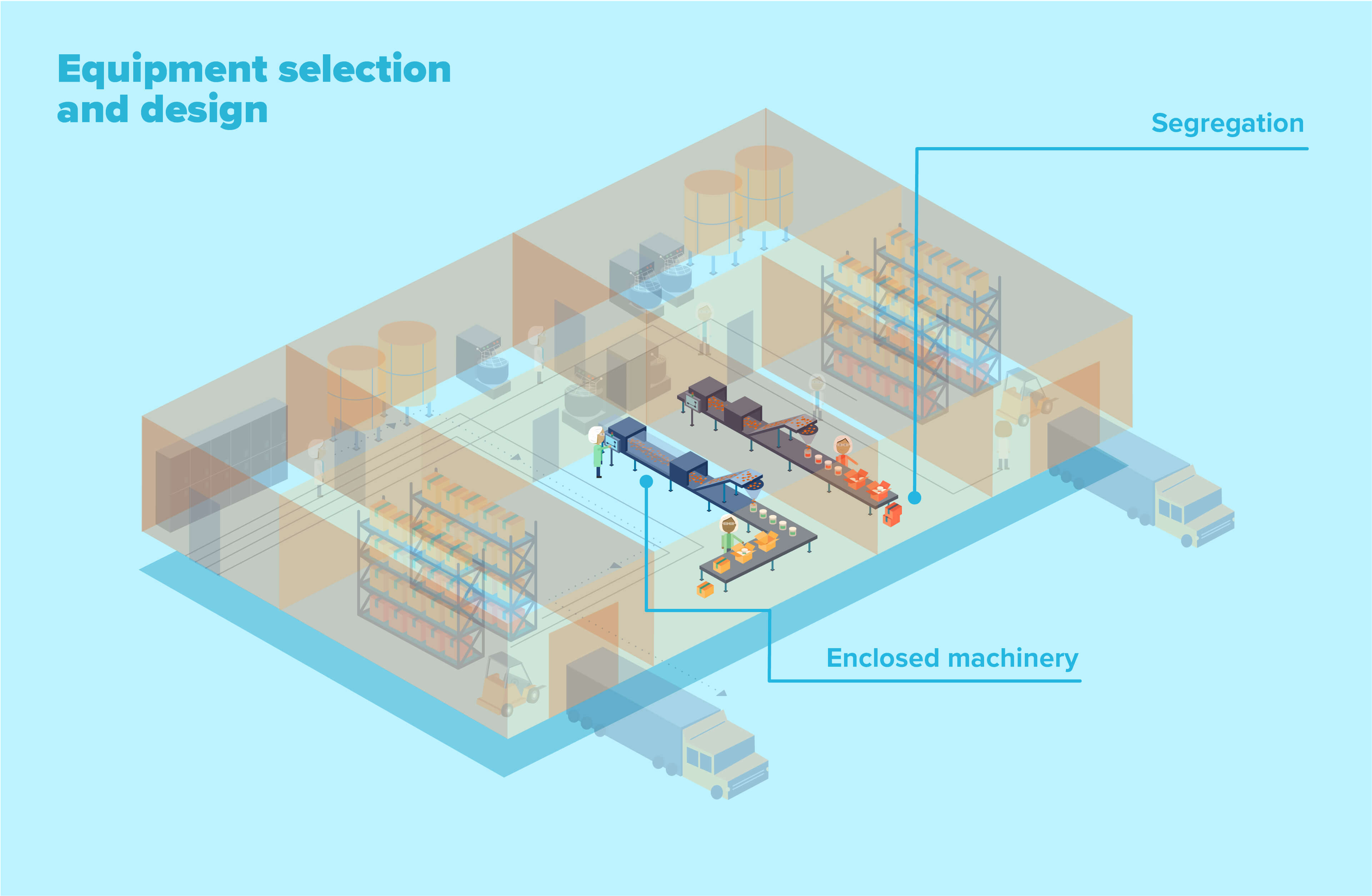

Equipment selection and design

Equipment used to produce allergen-free foods must be suitable, not only for the ease with which it can be cleaned but also for segregation. Some machinery may have a roof over any food-bearing sections to prevent contaminants from falling onto the food. Others have a plexiglass enclosure, which provides greater segregation for the product.

There are several considerations when selecting equipment for an allergen-free processing facility, which are best written into the design guidelines for the engineers.

This considers the ease with which equipment can be cleaned and kept clean, both inside and outside. For example, pipes and pumps need to be drainable so that no liquid remains and contaminates the next batch. Older equipment may need to be disassembled to be cleaned, which is a time-consuming process. Newer equipment can be cleaned in place (CIP) without disassembly, and this is a big improvement in hygienic design.

This is best accomplished with enclosed machinery.

Give careful consideration to the necessary filtration systems, air conditioning, airlocks, and other equipment needed to safely and properly control airflow.

Ensure that most of the equipment’s moving parts can be accessed and repaired without having to access the food contact area.

Machinery has to be flexible to manage a range of conditions.

Sanitation

Sanitation is the process of keeping the facility, raw materials, and process lines clean to avoid contamination and remove any allergens that might have contaminated equipment. You must develop and validate robust sanitation procedures to ensure that they can remove allergens. Quality assurance (QA) should be actively involved. When scaling up, remember that it is more challenging to clean a large-scale production facility than a small test kitchen used during development.

Cleaning requires a lot of forethought. If equipment can be cleaned in place, the CIP circuits will need to be designed and validated to prevent cross-contamination and eliminate allergens.

Each area and type of product has to have its own utensils, which need to be cleaned separately from utensils from other areas. Use color-coded utensils to identify their use and possible allergen contact. This ensures that white tools, for example, are washed separately from purple tools.

Environmental monitoring for air pressure, flow, and the possible presence of allergens is important and should be considered part of GMPs. Testing for allergens has become straightforward and easy. Swabs that can detect low concentrations of allergens by a change of color or luminometry are readily available. Due to the specificity of the tests, there is one type of swab for each allergen.

Unidirectional flow of residues to manage allergens in food manufacturing

The movement of waste products through a facility is usually overlooked. Food residues and production waste (e.g., bags and pails) can carry allergens, risking cross-contamination of other products. This can be avoided by ensuring waste flows along paths out of clean rooms and into dirty areas.

Designing a retrofit to handle allergens in food manufacturing

Retrofitting an existing facility is a common way food manufacturers expand production. This can be a challenge, especially for older factories that were built when allergens weren’t top of mind. An existing building can be retrofitted to create a separate space or an isolated production line within an existing building to handle allergens, segregated from the rest of the plant. Retrofits can involve building a new room or upgrading an existing room and the machinery in that room.

This requires segregated warehouses for raw materials, isolated production lines, airlocks, personnel segregation, and even dedicated HVAC/mechanical support systems.

For an example of how this design and construction can be accomplished without interfering with ongoing production, read about this baked goods facility retrofit, which used a prebuilt, modular electrical room to bypass an electrical system that would have been prohibitively expensive to upgrade.

The older the plant, the more challenging a retrofit will be because such buildings were not built with segregation and sanitation in mind. Sometimes just building a wall is not feasible or there is a hundred years’ worth of dust collected in the walls.

Retrofitting a plant may involve segregating by building a GMP cocoon around the process line. This separates the clean ingredients as well as possible so the company can avoid having to use a warning label.

The factory will need QA to develop standard operating procedures, written in a way that allergens are considered chemical contamination and treated as such. The products that are clean are treated as if they were pharmaceuticals.

It is imperative that the proper handling and flow of materials is incorporated into facility design and layout to control the movement of allergens.

Consider the necessary filtration system, air conditioning, airlocks, and layout of rooms during the initial design phase.

Allergens in food manufacturing can be managed properly during the design and construction of food production facilities and process lines with the help of a proficient and experienced design-build firm. CRB designs to the highest standards, using food industry experts who consider food safety and allergens in every project. CRB has expertise in all aspects of sanitary design, providing input to ensure that safety, flexibility, and efficiency are taken into account.

Let’s talk about how to safely handle allergens in your food processing facility.