6 innovative food processing technologies

The food & beverage industry is in the midst of an evolution in food processing technologies. Manufacturers are trialing new products, feeding consumer demand for convenience and variety. Here we delve into the most important emerging food processing technologies.

A confluence of factors have come together to make this era remarkably fertile ground for innovations in food processing. Of course, the need to ensure food safety has long been a driver of innovation. But now, the industry is seeing consumer preferences play a greater role than ever in the adoption of new food processing technologies.

Implement Innovation

Our food experts can help you adopt new technologies and improve your manufacturing process.Consumers want more convenience, which they find in the form of shelf-stable products. There’s also a growing market for health and wellness products, meaning food processing technologies are needed to support the preservation of ingredients and the use of probiotics. Perhaps most importantly, manufacturers and consumers alike want more food, made more efficiently, to feed the world’s ever-growing population. Combine all of this with the need for enhanced food security and an expanded range of distribution and it’s no wonder the entire industry is enthusiastically embracing new food processing technologies.

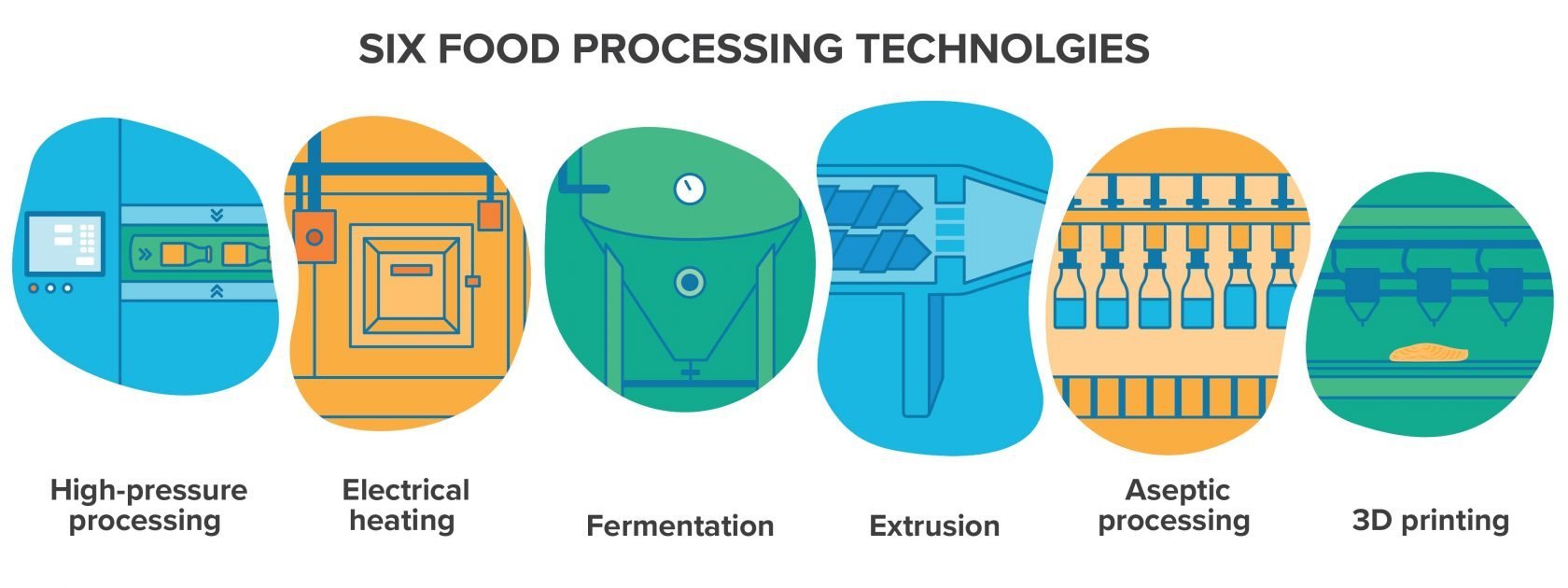

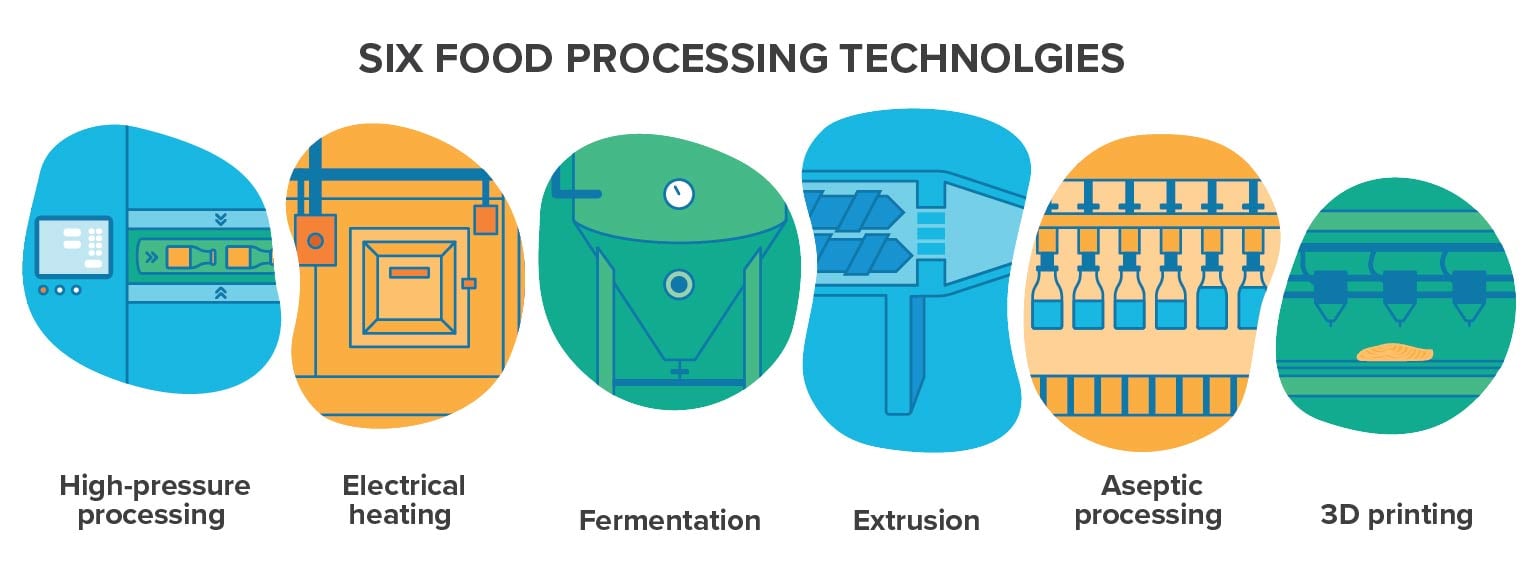

Some innovative advances have been adopted already by many producers (HPP and aseptic processing), others are still gathering momentum (extrusion), while a few remain in the experimental phase (3D printing).

Extending shelf life

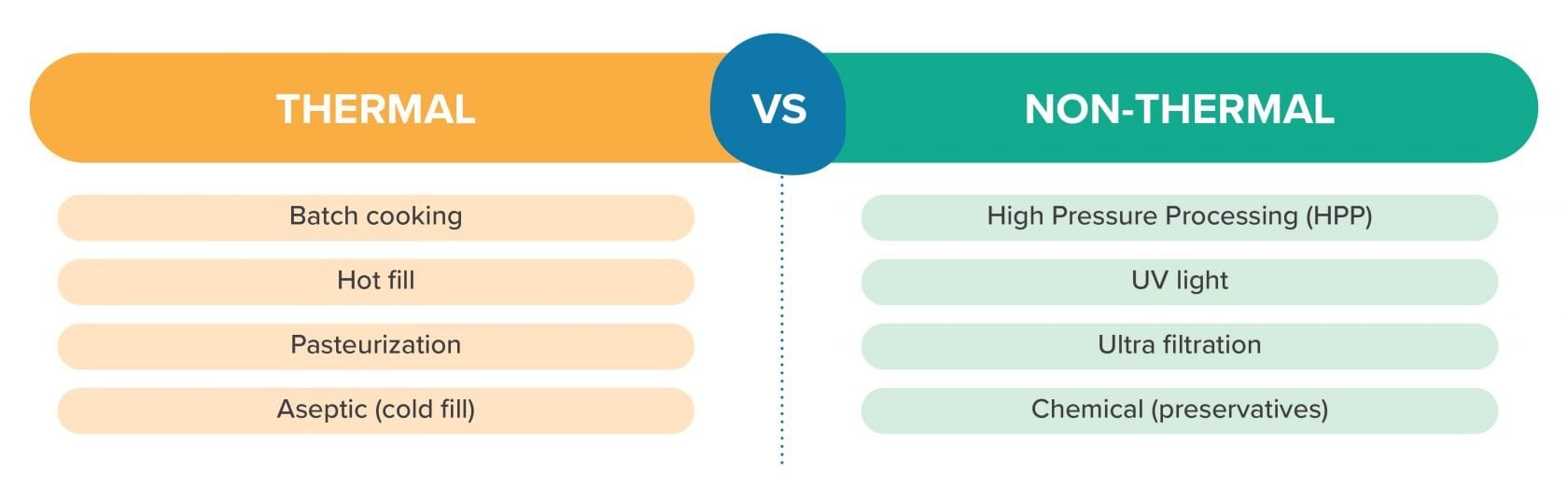

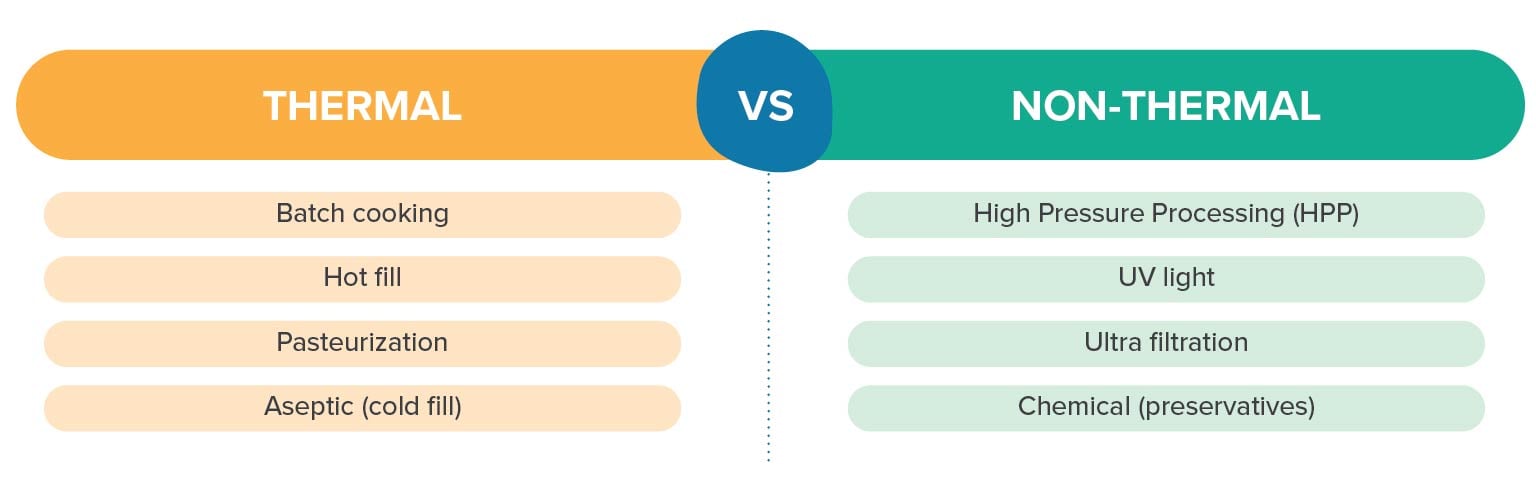

Food products tend to have a short life due to spoilage caused by enzymes or microbial contamination. There are processing techniques, such as preservation steps that decrease microbial load and inactivate enzymes, that extend shelf life. These steps can be used in-line (applied during processing) or in-pack (applied after the product is packaged) and are either thermal or non-thermal.

These processes must balance quality and safety. The design of food processing technologies also takes into account the need for flexibility, increased run times, lower cost of production, and reduced carbon footprint during processing, storage, and distribution. Flexibility includes planning for shorter runs of specialized and multiple products, brief cleaning times, and rapid changeovers.

1. High-pressure processing (HPP)

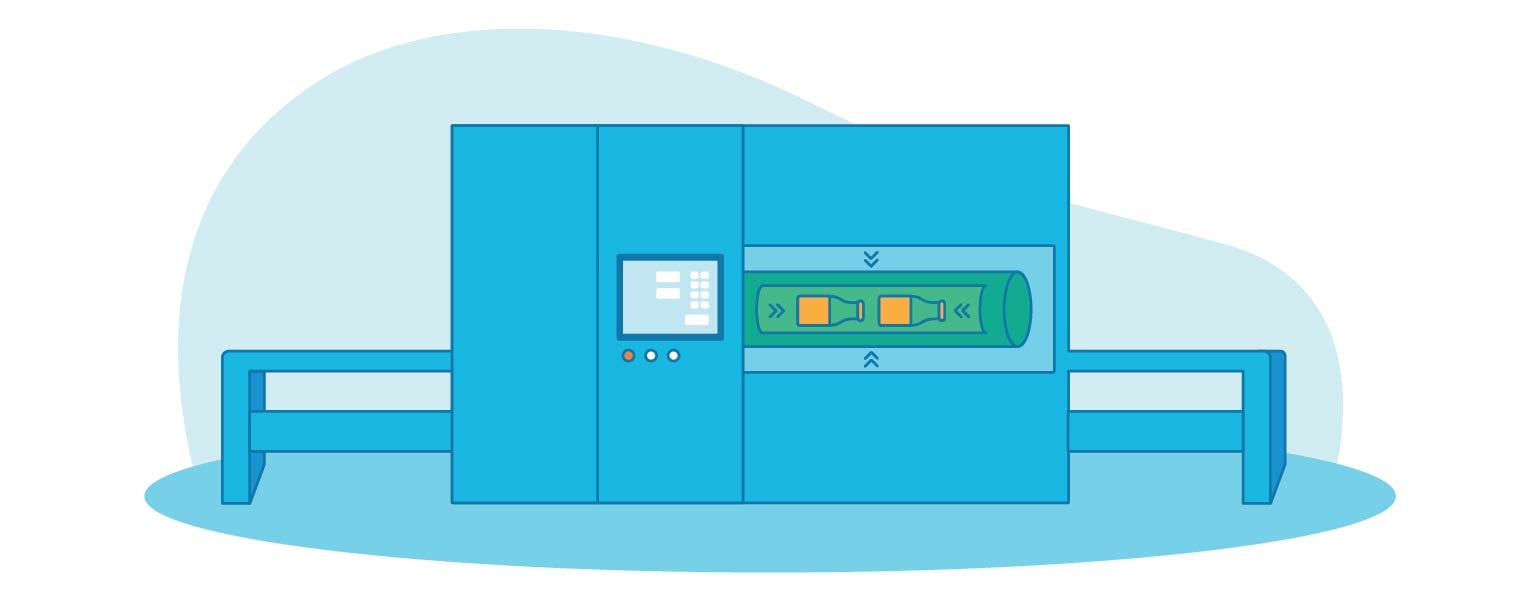

HPP is used to rapidly kill vegetative microbes, inactivate viruses, and denature enzymes without the use of heat. It is a batch process that applies high pressure—approaching 100,000 psi or 600 MPa—once the product is packed in its final container. HPP is the most commonly used emergent food processing technology.

Benefits of HPP

- Minimizes treatment time

- Simple scale-up

- Commercially viable

- Preserves nutrition and flavor

- Does not kill spores, meaning it can be used even for probiotic products

- Tends not to brown fresh fruit and vegetables, making it ideal for guacamole/avocado packets

- Can be used with garnishes and complex finished products

- Independent of product mass, size, or geometry.

Challenges of HPP

Despite its popularity and benefits, HPP comes with significant challenges.

Alteration of final product

While generally preserving nutrition and flavor, the process can affect the color, texture, and flavor of some fruits; the color, texture, and fats in meats; and can open shells in some seafood products.

Throughput needs

It’s important to consider current and future production needs. As a batch process, HPP can add to cost when compared with continuous processing techniques.

Regulations

You need to judge that HPP is the proper preventative control for your product. As with any new technology, it takes time for regulatory authorities to validate equipment and processes, which they do on a product-by-product basis.

Food safety

There may be a need to control additional elements, such as water activity control or a refrigerated supply chain.

Training and labor

Labor costs may be higher because HPP needs manual loading and unloading and also requires specialty skills and training to operate the high-pressure system.

Specialty packaging

Packaging must be flexible (i.e., not rigid) to allow for equalized pressure throughout the product. This maintains the integrity of the package. Metal, glass, and paper aren’t suitable for HPP as the package must be compressible and impermeable to water. The packaging material supplier and HPP vendor should have tested film and container closure systems with a proof-of-concept test.

For example, a container of hummus with toppings covered with a flexible film can withstand the pressure and be processed in a water bath. But a rigid plastic lid must be added after HPP to avoid water filling the gap between the film and the lid.

Cold storage and transport

Many high water activity foods, like cold press juices, smoothies, or hummus, must be refrigerated after treatment, necessitating a cold supply chain.

Equipment is capital-intensive and large

In addition to requiring capital to procure HPP processing equipment, the equipment is heavy and difficult to move into an existing plant, which affects a facility’s footprint and design. You also need to account for ergonomic and safety considerations.

Utility upgrades

The strain on existing facility utilities due to the increased demand of equipment sanitation or air drying after HPP could require significant process utility upgrades.

Given the many factors to consider, proper preparation is critical for a safe and successful installation and start-up of HPP within a food production facility. High on the list are the capital expenses of equipment, labor, and utilities. Many companies, after an initial investigation reveals these costs, opt to work with a third-party processor dedicated to HPP.

2. Electrical heating

Electrical heating allows processors to use sustainable energy and rapid heating to replace fossil fuels and decrease the carbon footprint of the product or processing facility. Among the electrical heating methods, microwave, radio frequency, and ohmic have emerged in the industry, and other food processing technologies, such as induction heating, are being developed.

- Continuous ovens use microwave or radio frequency energy as alternative methods for low-impact drying. This removes water activity using less heat and energy than oven baking.

- Tempering units accelerate the thawing of meat for processing, as well as reduce the time to freeze-dry and dehydrate some products.

- Continuous flow systems, using microwave or ohmic, heat and sterilize liquids, purees, soups, fruit pieces, and products that can be pumped.

- Microwave-assisted retorts improve the quality and throughput of in-pack sterilization.

Electrical heating applications

Meats

Microwave ovens can be used to temper large blocks of frozen meat, which speeds up thawing and reduces energy consumption. Continuous microwave ovens are used for cooking bacon and to reduce water activity, such as for finishing bacon bits. Several manufacturers combine microwave heating with steam, radiant heating, or air impingement for improved cooking velocity while browning the outside of the products to enhance cosmetics and flavor.

Spices and fruits

Microwave heating is used to sterilize agricultural products, such as spices. It has the benefits of a relatively short heating time and low temperature. The sterilized product retains many of the organoleptic properties of its fresh state, including appearance and taste. Microwave heating also uses less energy than oven heating.

Pet treats

Bully strips—a chewy dog treat made of beef muscle—are coated with a flavoring that needs to be dried before packaging to prevent microbial growth. One company reduced water activity below the critical threshold through a combination of oven drying and microwave heating. The combination of equipment took up less square footage, meaning a smaller facility footprint and reduced construction costs.

Aseptically processed foods

Continuous flow electrical heating is used to produce high-quality products that are then packed aseptically, either in bulk, such as sweet potato puree, or for retail, such as soups. Electrical heating is rapid, doesn’t require hot surfaces, and can thicken products. This minimizes the loss of nutrients and changes to the texture and prevents products from browning and caramelizing.

The FDA has approved microwave and ohmic heating for aseptics, allowing the production of high-quality products using less energy. Aseptically packaged foods are usually shelf-stable, which eliminates the need for refrigeration and therefore reduces a manufacturer’s carbon footprint during storage and distribution. The use of microwave as an alternative to heating opens up the possibility of using renewable energy directly instead of steam.

Packaged foods

Sterilizing packaged foods with microwaves can speed up production and allow the use of sustainable energy for products with a long shelf life. Several producers use this regulatory-approved application.

Electrical heating challenges

Initial capital investment

Plan to make a larger initial investment in equipment and utilities for electrical heating systems. They are more costly than conventional heating.

Product development

To implement electrical heating technologies, you may need to revisit product formulations to match the capabilities of such technologies.

Limited equipment suppliers

Electrical heating has been widely accepted in tunnel applications (e.g., drying and tempering) but only slowly adopted for liquids due to limited offerings on the market. This should change as sustainability efforts increase in the industry.

Control and instrumentation

Electrical heating offers instant on and off, but that means that changing incoming materials can lead to under- or overheating. You must have a robust control system that can adapt quickly when inputs change.

Personnel training

Due to the intricate and highly technical nature of electrical heating equipment, plan to train maintenance personnel on ongoing operation, preventative maintenance, and repairs.

3. Fermentation

Fermentation is far from a new process, but the technologies we use to produce standbys—like beer, wine, yogurt, kimchi, kombucha, and sauerkraut—are always evolving. There are also newer applications of fermentation in food production, including ingredients still in product development.

Types of fermentation

Atmospheric fermentation

Atmospheric fermentation occurs under normal pressure with minimal sterility control, often in an open vessel. It requires a seed organism robust enough to grow without controlling the sterility of the batch. This is typical for traditional fermented foods (e.g., beer, sauerkraut) that can be made at home. Some yogurts are made this way, though those using a proprietary strain of bacteria to achieve desired organoleptic characteristics may require more stringent sterility controls.

Under pressure, sealed fermentation

Pressurized fermentations open up new avenues: the use of novel organisms or processing routes that cannot be made via atmospheric fermentation. Under pressure, sealed fermentation is a highly sanitized or sterile fermentation process that uses a pressure-rated vessel. This sterilization step needs to be added to the process to rigorously prevent cross-contamination in the environment, including during filling.

As such, needing steam on-site and the boilers and steam generators for SIP has a significant impact on a facility’s design.

New fermentation applications

Cultured and mycelium meat

The overarching principle of processes used to make mycelial products and cultured, or cell-based, protein products are similar. They start with a live organism “seed” or starter culture. The starter culture is grown in bioreactors under tightly controlled conditions until there is enough product to harvest.

Flavor ingredients

Companies like Givaudan are using fermentation to produce food ingredients, as well as health and wellness products.

Fermentation challenges

Bioreactor fermentations at an industrial scale are not as simple as applying wine-making techniques and equipment. Let’s dive into some differences.

Sterility is paramount

Steam-in-place (SIP) is not required for some beverages using sugar-based fermentations (e.g., beer, wine, and kombucha). Instead, a simple clean-in-place (CIP) will do the trick. But many newer food product fermentations (e.g., probiotics) depend on a sterile environment that favors the growth of a specific microbe. This need for sterility exists in industrial settings because contamination during fermentation may lead to the growth of undesirable organisms, rather than the seed culture.

Besides maintaining food safety, sterility ensures batch-to-batch consistency. Excellent examples are the production of probiotics and those seeded with a bovine cell line for cultured meat.

Post-harvest consistency can be tricky

Making sauerkraut at home is a process that uses the microbes naturally present on cabbage as a starting point for fermentation, and results can vary from batch to batch. Industrial fermentations that rely on organisms, however, need to achieve consistent results—in terms of the concentration of cells or compound of interest—at large scales, batch after batch. Temperature and media ingredients need to be consistent, and there has to be a way to manage the large amounts of heat and off-gassing occurring during fermentation. The product needs to be standardized after harvest to maintain label consistency.

Sterile seed trains require specialized equipment and staff

An organism that can’t outcompete other microbes needs a sterile environment throughout the seeding train, from small-scale cultures in a fume hood, through ever-larger fermentation vessels until the production-size bioreactor, which could be as large as 100,000 L. This demands a complete train of equipment—some of it pressure rated—and steam generation to sterilize it.

It also requires specialized staff trained in sterile techniques to handle the small-scale cultures. And you must give special attention to cleaning. For example, the ports and connections are vulnerable to contamination if they’re not cleaned and sterilized properly. One issue is that nozzle connections and ingold fittings can develop a crust of organic solids that survives SIP because CIP wasn’t complete. The contamination can then reseed through the ingold fitting.

High production costs and low yields

In addition to the need for specialized equipment, appropriate utilities, and expert staff for fermentations, other aspects of the process can increase costs.

Productivity is low.

Obviously, the more product a facility produces, the lower the price per pound in terms of overhead. Maximizing cell density is one of the biggest challenges in the industry right now and, at only 1–20%, this limits the yield coming out of the fermentor.

Media is expensive.

For cell-based meat, media is the most expensive part of production. Growth media contains ingredients like amino acids, recombinant proteins, micronutrients, and, in some cases, fetal bovine serum, some of which can be prohibitively expensive.

Batch time can be long.

Much of the rest of the food industry runs at rates of hundreds of units per minute, while these complex fermentation batches can take one to two weeks to mature. Combined with relatively low cell densities, this further limits yield.

4. Extrusion

High-pressure extrusion is being used to manufacture many new products, including high-protein cereal, plant-based proteins, and salty snacks like cheese puffs. Extrusion imparts a unique texture to food, binds ingredients well, and is sensitive to raw material composition, tending to work better with high-protein/low-starch formulations. It uses moisture, high temperatures, and mechanical energy to mix the ingredients and rapidly cook them in seconds. The result is a product that can be dense or puffed.

Pet treats is a burgeoning market

Extrusion has long been used in pet food to produce kibble, but this technique is finding new applications. Co-extrusion has emerged as a method for adding functionality and flavor to treats. Tuffy’s Pet Treats makes semi-moist pet treats this way. Some pet treats are composed of a soft flavor center inside a harder shell, like fake bones or chews. In this case, each formulation is processed with a different extruder, then combined in the final product.

Extrusion challenges

Throughput

Successful extrusion needs to impart a lot of energy in a short amount of time. This requires smaller volumes relative to the surface area. Often, scale is achieved by adding more extruders.

Utility consumption

The mixture often needs to be heated to >160°F under high pressure for the texture to form properly, requiring a boiler system and drawing significant electricity. This steam generated by pressure and heat needs to be removed through appropriate HVAC systems.

Scaling up

Scaling up extrusion takes specialized equipment and expertise. Recipes from a test kitchen—even those using smaller extruders—don’t necessarily scale well. Plan to expend a lot of time and materials to experiment to scale up a recipe and process. Partnering with a university food science lab or an equipment supplier can help.

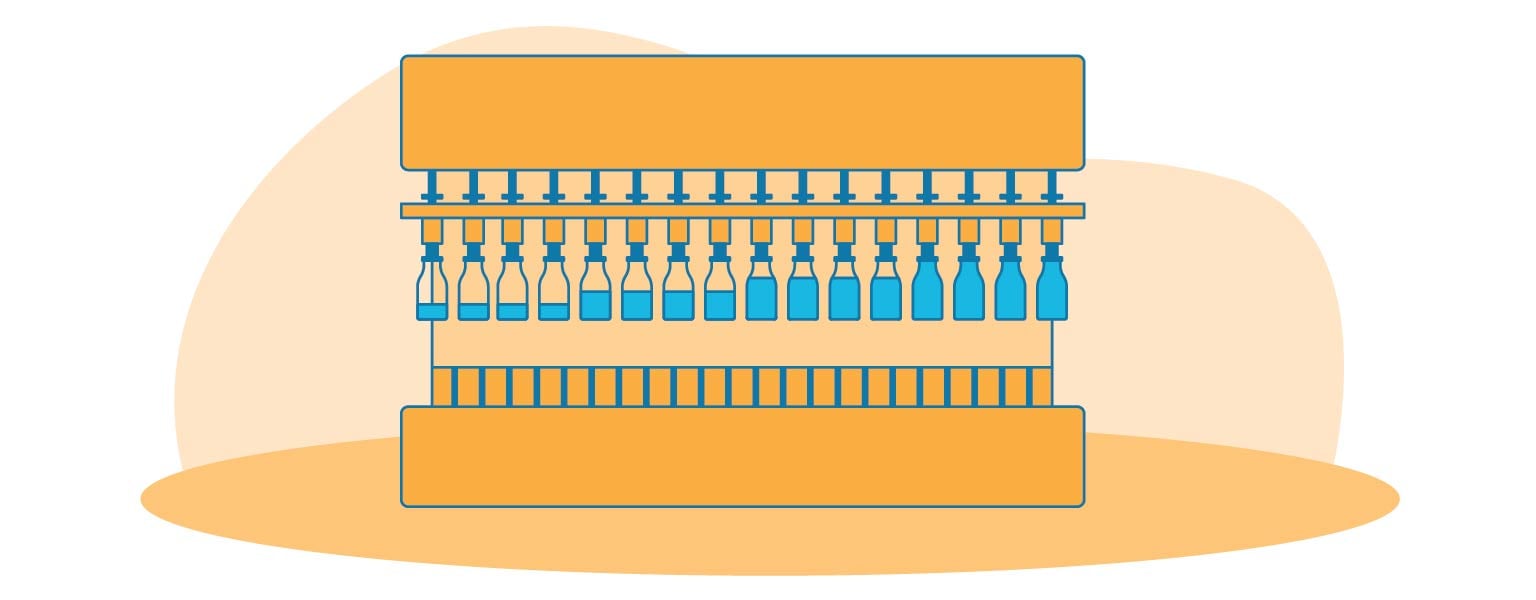

5. Aseptic processing and packaging

Aseptic processing helps manufacturers reach new customers and expand the range of their offerings by removing the need for refrigeration during transport and on store shelves. It is used to make shelf-stable animal and plant-based products, liquid eggs, puddings, soups, vegetable purees, and bulk ingredients.

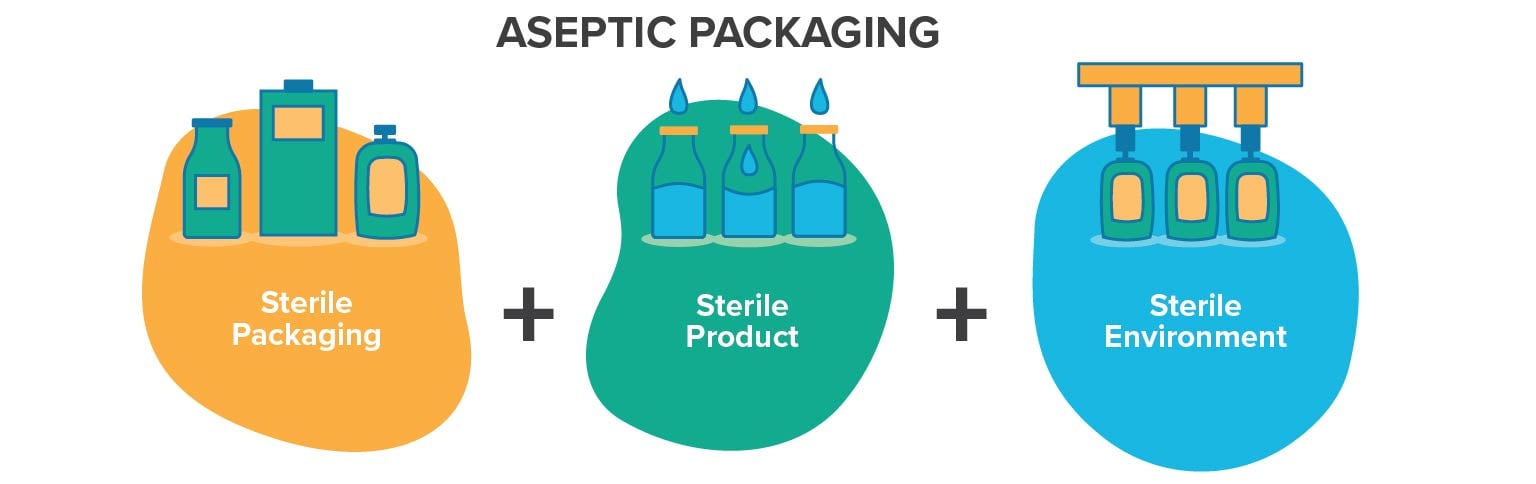

Aseptic processing is a combination of continuous thermal treatment and advanced packaging. It involves filling sterilized containers, in a sterile environment, with product that has been sterilized, typically by heating, and cooled prior to filling, ensuring microbes are killed in the food product and not reintroduced during packaging. Aseptic packaging is independent of the processing line, thus making available an almost unlimited variety of packaging sizes and shapes.

By extending the shelf life of products and allowing large packaging sizes, this food processing technology is important for companies interested in national distribution, food service, and ingredient or bulk product sales. By removing the need for refrigeration, distribution and warehousing are much simpler and products can reach farther than before.

Compared to canned goods, this food processing technology allows some high-moisture products to be stored at room temperature while maintaining a fresher taste or appearance. By combining rapid heating with rapid cooling, aseptic processing increases nutrient retention and minimizes flavor changes. Aseptic processing using emerging technologies, such as microwave or ohmic heating, may also allow the industry to use sustainable energy sources instead of steam from fossil fuels.

Aseptic processing challenges

The upsides might have you sold on aseptic processing, but there are also challenges—from testing to see if a product is compatible with aseptic processing, to ensuring food safety and proper employee training—that you must consider before adopting this food processing technology.

Adds cost and complexity to operations

Products must be sterilized and packaged in a controlled environment. This means all process operations need to be coordinated, which adds to the complexity of production. Also, the need for sterility requires specialized equipment, as well as filtered air and steam traces, so your initial capital investment could be two to three times larger than for fresh production.

Regulations and safety

Having a well-rounded food safety plan ensures products meet FDA regulations. Every product needs to be filed with the FDA, including monitoring and documentation of all critical control points, which adds a burden to startups. Validation and documentation require a process authority and registration with the FDA. Validation must show the process maintains sterility up to the point of being sealed in the package.

Higher maintenance and training

Ongoing training is critical as aseptic production requires higher maintenance. The long cleaning and sanitation cycles mean more downtime. Additionally, evolving packaging requirements increase R&D costs.

6. 3D printing

This is one of the most exciting innovations; 3D-printed candy is already on the market. Sugar Lab prints confections made solely of sugar at a rate of one per minute. Beyond applications like this, 3D printing as a food processing technology is still largely experimental.

It’s an option startups are considering as they experiment with cultivating the components of meat—fat, tissue, and blood—then combining them into a cut of meat, like a steak. A 3D printing system, such as one from MeaTech, could be a viable way to combine those components. But there are numerous challenges—notably the cost of media, cleanrooms, and equipment—standing in the way of widespread adoption of 3D-printed meat. One of the benefits of 3D printing is the potential for a high degree of automation on the food processing line.

3D printing challenges

Beyond the cost of 3D printing certain products, throughput remains a general challenge. As with extrusion, if a process needs more 3D printers, expenses increase. You may also have to add a kill step after assembly, or a sterile assembly environment, to ensure food safety—but that could alter the organoleptic and nutritional properties of the food. These challenges require a considerable R&D effort beyond existing kitchen techniques.

Planning for new food processing technologies

Planning for advanced manufacturing requires a willingness to devote the resources and time needed to make changes. Make sure that management, marketing, R&D, QA, engineering teams, and trade partners are aligned early in the process to identify pain points.

- Experienced engineers will support the validation and qualification of new equipment and processes, as well as uncover hidden costs. These can include training, validation throughout the lifecycle of the product, commissioning, and possible scheduling delays.

- R&D may need to adapt an existing formula to match the new process, such as when a refrigerated formula is converted to one that is shelf-stable.

- QA will handle the training, validation, and documentation to ensure food safety. Also be sure to involve relevant regulatory bodies from the start for qualifications, including the FDA, USDA, organic certifying bodies, and international regulatory agencies.

- Production records need to be documented and properly stored, including regulatory and quality certifications (e.g., organic, Kosher). You must make decisions on paper versus electronic storage, statistical process control, and the details of supply chain management.

- Trade partners can provide input on the constructability of the facility. When they’re involved early in the design and construction process, they will identify any unique challenges at the outset. This allows the team to determine high-quality and cost-effective solutions without slowing the timeline.

It’s an exciting time in the food & beverage industry as food processing technologies continue to evolve to meet consumer desires and improve the ways manufacturers make, store, and distribute food.

Want to learn more about new food processing technologies? Reach out to us!