During the information gathering phase, our control systems integration team shares a detailed questionnaire with stakeholders. The goal of this phase is to begin thinking about the organizational drivers that will shape the control philosophy—some of which you may be considering and clarifying for the first time.

During the team workshop phase, stakeholders gather with our control systems integration team to share insights, collect cross-functional feedback, and hear from key stakeholders and operators who will help put the control philosophy into practice.

The goal of this phase is twofold. The first goal is to draft the philosophy document itself. The second goal is less tangible, but just as important—it’s about building consensus among different teams, including operations, engineering, and IT, and making sure that all key stakeholders leave the room as advocates for the vision articulated in the control philosophy.

The review phase is just as it sounds. Our control systems team circulates the draft control philosophy, gathering feedback and applying revisions until a final, approved document is ratified.

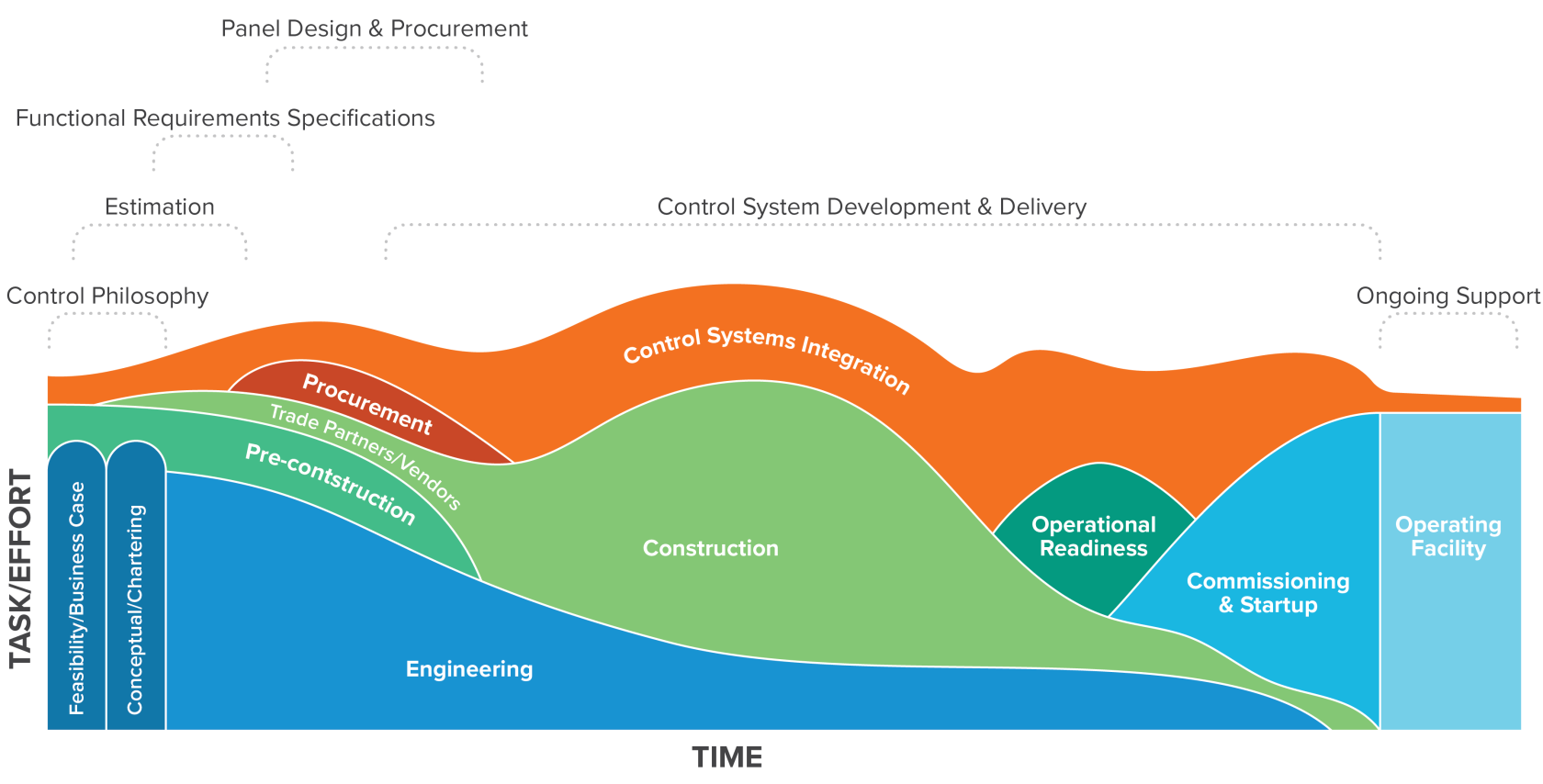

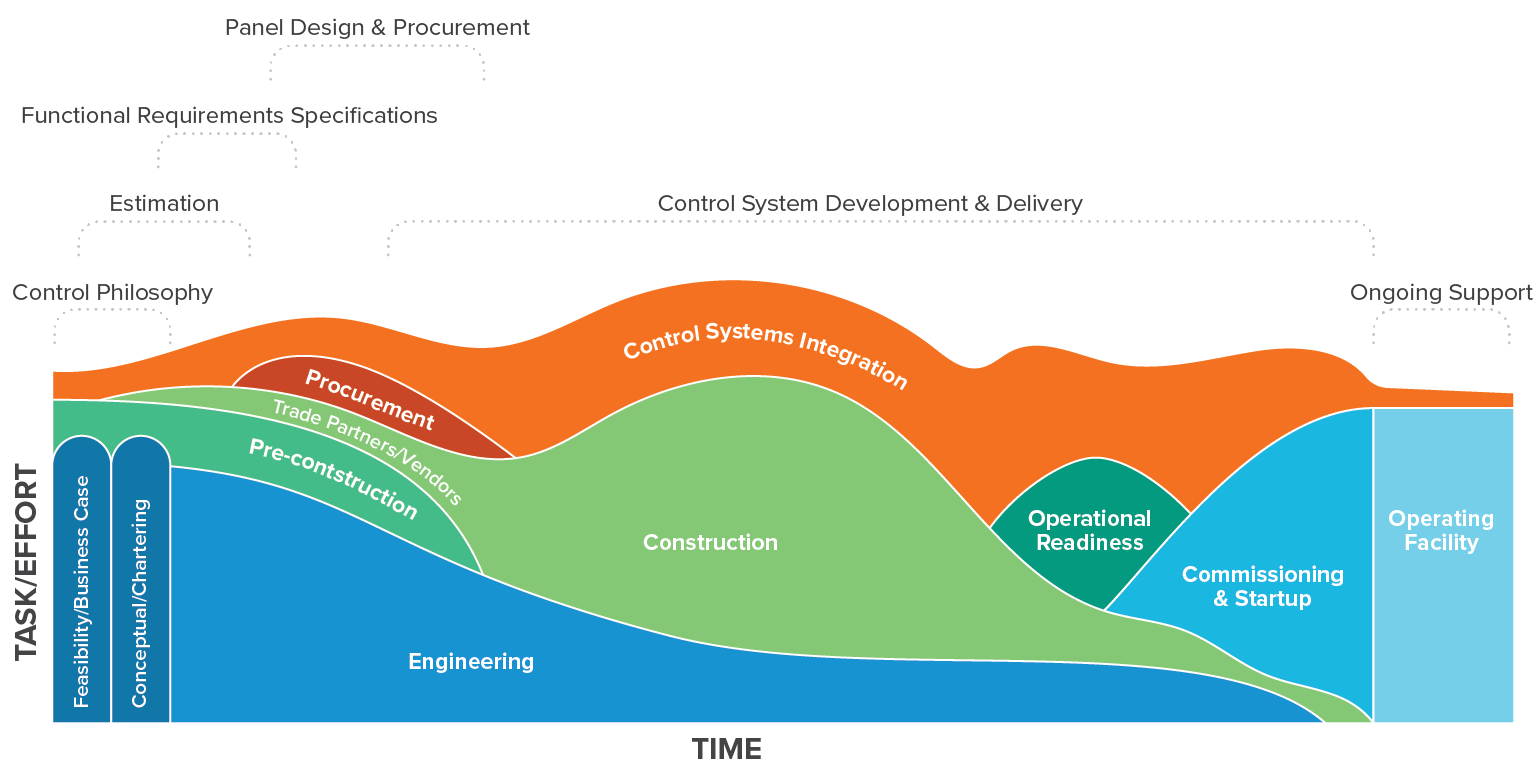

Now you have a control philosophy. What’s next?

As you move ahead with your capital project, digital transformation journey, or any other initiative that creates an opportunity to harmonize operations across your organization, you can call on your control philosophy to continuously guide you toward the next right decision.

It’s important to note that your control philosophy is not a static document. Think of it like a dynamic source of information; as your organization and the context in which it operates evolves, so should your control philosophy. For that reason, be sure to review and revise it each time you kick off a capital project. Or, if there’s no capital project on the horizon, plan to revisit.

To move forward with confidence, start with a control philosophy

Whether you’re a large organization or a small one, an innovative startup or an established powerhouse in your industry, you face immense complexity. Which technologies will move you forward, and which will hold you back? Where are the roadblocks preventing you from achieving true data integration across your plant, and how can you remove them? What will you do tomorrow, when the market shifts and you face a new level of demand?

In this complex landscape, your control philosophy puts an “X” on the map and gives you the navigational tools you need to reach your business goals. You’ll have new momentum behind you, and you’ll get where you want to go sooner—with fewer detours along the way.

To kickstart your control philosophy development process, .