Before you begin

1. Know your business case.

For a control systems integrator to help you move forward effectively, you need to know where you’re going. Is this the right time for a greenfield project? Or is a retrofit more suitable to your situation? Perhaps you simply want to know if you can meet demand more efficiently by tapping under-used capacity that you already have.

A well-defined business case is the key to answering these questions and mapping a successful path forward—a path that aligns your current financial resources with your future business objectives. It should be grounded in historical data while looking ahead at predicted demand, giving you the fundamentals you need to understand how your business will stay competitive over the next 5, 10, or 15 years.

From this big-picture analysis, you can begin to drill down to the practical implications of business growth. How will your headcount change over time to meet your business drivers? What new equipment or storage solutions will you need? What sort of utilities will you require to support future expansion? How soon will your investment in these resources and capabilities generate a return?

With your business plan clearly defined, you’ll have the context that your control systems integrator needs to help you make confident decisions about your plant-floor automation strategy. Your integrator will be able to guide you toward solutions that align with your business drivers while positioning you for greater profitability and growth. In other words, the business plan provides a roadmap for everything that follows. By sharing that roadmap with your integrator, you’ll get where you need to be much more efficiently.

2. Define your manufacturing process.

A control systems integration strategy isn’t simply layered onto facility design—it’s part of facility design, and it needs to be developed with a deep understanding of your end-to-end manufacturing process and its constituent parts.

That’s why it’s important to come to your control systems integrator with a well-defined map of your complete manufacturing process. That will position your integrator to identify and eliminate operational silos and build pathways for exchanging data between your technologies, networks, OEM-provided equipment, and other sources—from one end of your manufacturing process to another.

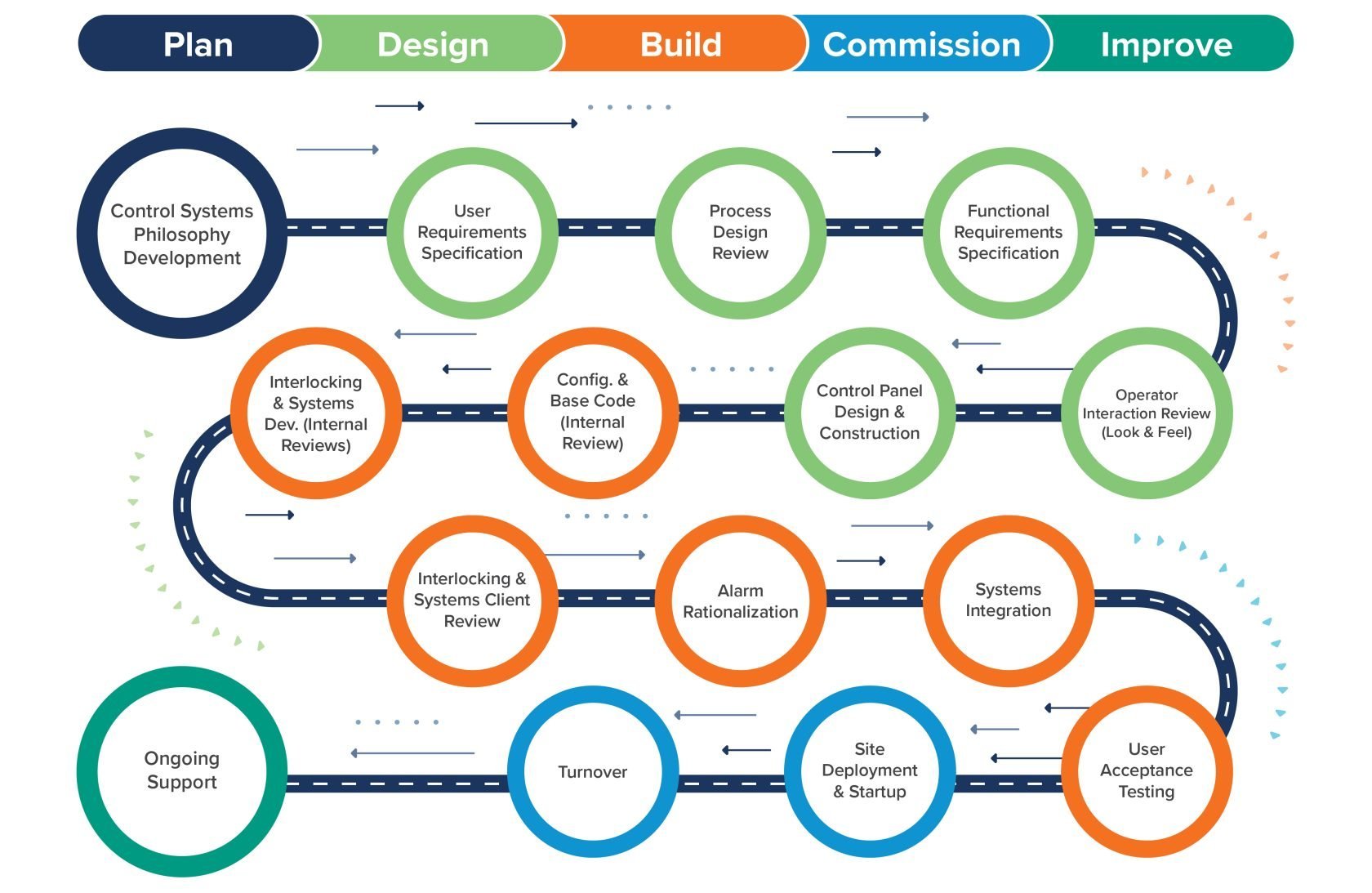

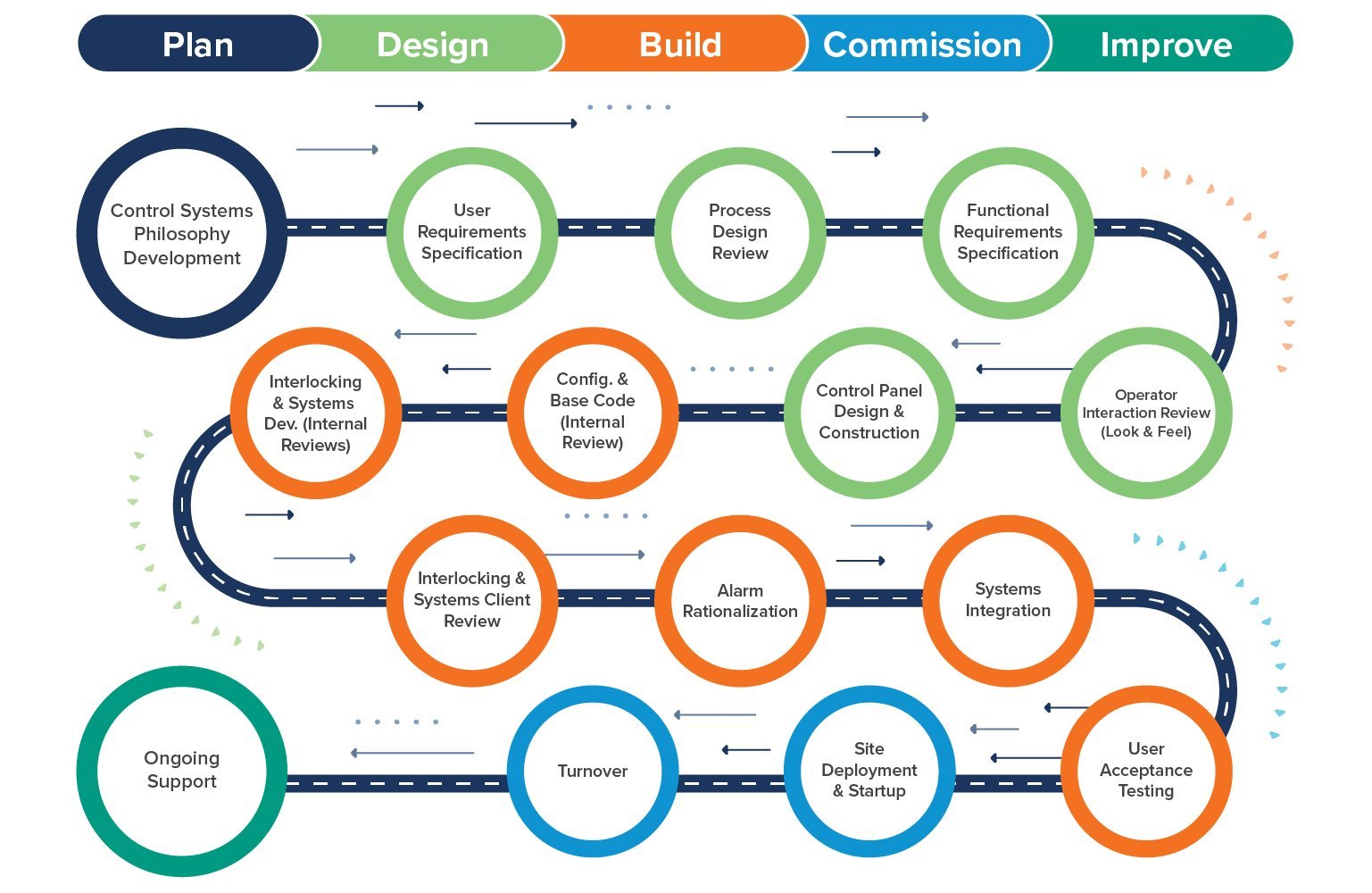

3. Develop a control philosophy.

A control philosophy is a high-level document that defines your organization’s unique approach to digitalization. Your business case and manufacturing process will help shape your control philosophy, as will external factors such as the nature of your industry and the supply chain dynamics that support it. The goal is to reach internal consensus about what digitalization means for your organization. That way, you and your control systems integrator can make decisions consistently and quickly as your project develops.

No two control philosophies look the same, but they should all include guidance around important factors such as your automation strategy, your tolerance for risk, your approach to collecting and utilizing data, your safety strategy, and your strategy for selecting key vendors.

Some organizations prefer to develop their control philosophy (or update an existing one) in partnership with a control systems integrator. A skilled integrator has the tools necessary to bring multiple stakeholders together from across your organization and lead them through workshops specially designed to help you tailor your philosophy to suit your operation and support your business needs.

4. Select the right control systems integrator for the job.

Selecting a control systems integrator may be one of the most impactful decisions you make in terms of your future success as an integrated and digitalized enterprise. Choose well, and you’ll reach your digitalization goals on the straightest possible path, gaining efficiencies and flexibility as you go. Choose an integrator who’s not suited to your industry or the scope of your project, however, and you may find yourself off-course.

The key to making an appropriate selection is to ensure that your needs and your integrator’s skillset are aligned.

What are your needs?

Your business plan will play a key role here. Use it to identify your digitalization objectives, what you need to meet them, and where your current gaps are in terms of internal capabilities. From there, you can begin to understand exactly what you need from your control systems integrator. For example:

- Do you need someone who can help you develop your control systems philosophy?

- Do you need cyber security expertise?

- Do you need ongoing post-startup support?

What is the integrator’s skillset?

Now that you understand your organizational needs, you can examine potential partners for a good fit. Technical skills are important, but so are the soft skills needed to help build consensus and alignment across a complex organization.

Technical skills

- Knowledge of your industry and its regulatory requirements

- Experience with automation technologies, network design, etc.

- Experience working with a broad range of OEMs and other vendors

- Extensive knowledge of ERP and MES infrastructure

- A deep understanding of data integration and management

Soft skills

- A demonstrated capacity to build organizational consensus

- The ability to collaborate with experts from across the project value chain and represent their needs throughout delivery, including plant operations, process engineers, utilities and IT experts, technical and trade partner leads, equipment suppliers, etc.