Umoja Biopharma, Inc.

Read More

Fresh Refrigerated Pet Food Plant Expansion Design

Refrigerated pet food plant with fine-tuned temperature and humidity control

Freshpet, a producer of all-natural dog and cat food, sought to expand pet food production at an existing facility to meet projected growth due to increased consumer demand. Freshpet uses a propriety process to produce their preservative-free food from real meat and fresh vegetables, which includes mixing and blending of raw materials, cooking, cooling and packaging. As a result, temperature and humidity control are critical to maintaining product quality.

The refrigerated pet food plant expansion includes the renovation of an existing 50,000-square-foot facility adjacent to the current production facility and a 90,000-square-foot addition. The expansion will create capacity to support approximately $540 million in net sales from the facility and could create as many as 200 jobs.

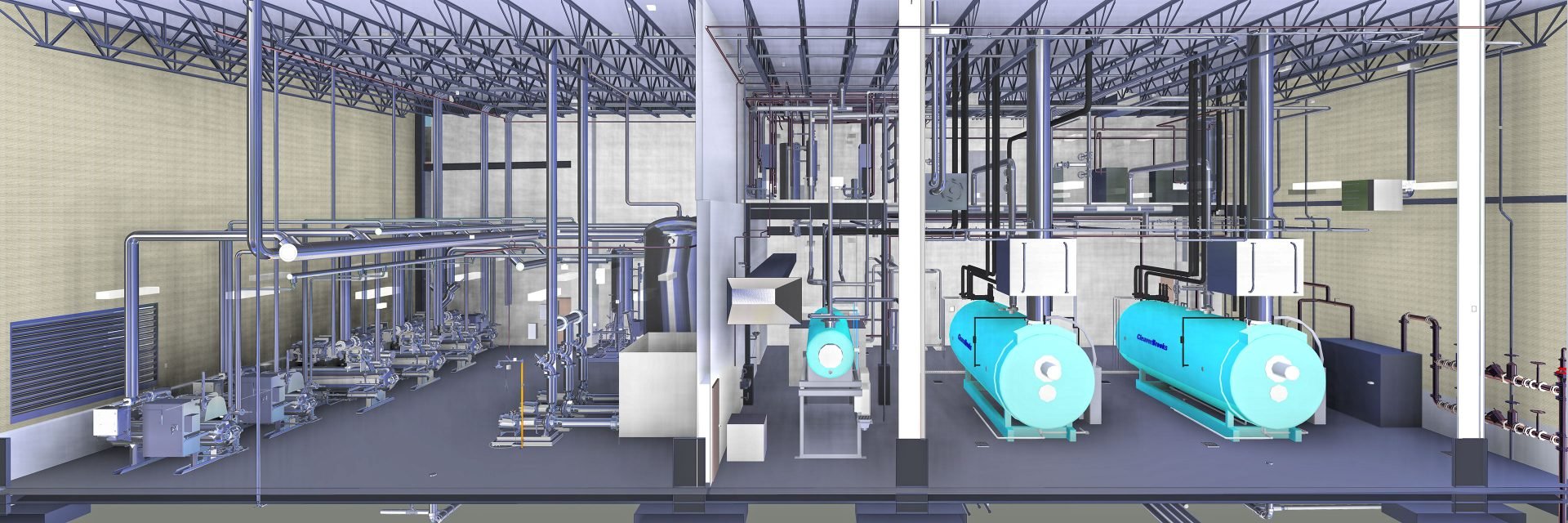

The addition houses the production space including climate-controlled docks, incoming freezer and cooler storage, two new refrigerated production lines, packaging and support functions. The renovated space includes offices, a pilot plant, research and development laboratories, quality laboratories, warehousing, cafeteria and loading docks. The entire facility is designed to food-grade standards and SQF Level 3 certification.

CRB designed a plant steam and condensate system to serve production equipment and HVAC systems, centralized ammonia plant, comfort and hygienic process HVAC systems, plumbing services, plant sanitization system, power system, complete lighting design, fire alarm design and performance specification of facility fire protection design.

A new 1,350-ton ammonia central refrigeration system serves the refrigerated spaces and process equipment with distributed ammonia refrigerant. The production spaces are cooled utilizing hygienic air handling units to maintain a cold and dehumidified hygienic air supply into the production spaces. Other spaces, including production coolers, loading and shipping docks and the finished product warehouse, are cooled using traditional ceiling hung fan coil ammonia evaporators. A tunnel chiller is supplied directly with ammonia refrigerant while a cascading water chiller is cooled using recirculated water chilled by ammonia.

Project Details

Client

Freshpet

Location

Bethlehem, Pennsylvania

Square Footage

140,000

Cost

$100 million