Target value delivery reduced spending by $800K, delivered state-of-the-art pet treat facility

The question facing Tuffy’s Pet Treats was never if they should build a new, state-of-the-art manufacturing facility.

The company, operated under KLN Family Brands, built a reputation as a quality-driven co-manufacturer for many of the country’s leading pet food brands, with 720 tons of dry kibble leaving their Minnesota facility each day. By 2019, though, consumer demand and processing innovations were driving changes in the marketplace. Premium, semi-moist pet treats were the future. To grow their stake in the global pet-related marketplace, Tuffy’s would need to grow their manufacturing scope in a new and innovative direction.

So, a new facility? Never an if. But how to get it done cost effectively and on a tight schedule—that was the question facing the Tuffy’s team when they turned to CRB and placed their trust in our ONEsolutionTM approach.

Project Details

Client

Tuffy's Treat Company

Location

Delano, Minnesota

Square Footage

174,000

THE CHALLENGE: Deliver a state-of-the-art facility cost-effectively and on a tight schedule

Cost control was a key driver. The new facility would serve co-manufacturers of all sizes, from high-volume legacy clients to niche startups seeking small initial product runs.

This created a challenge. If Tuffy’s overspent on the facility, that could translate to higher fees for their clients, presenting a barrier for the cost-sensitive startups that Tuffy’s was determined to support.

On the other hand, servicing such a diverse client list would require immense operational flexibility and close attention to safety—not an inexpensive prospect. To succeed, the CRB team needed to strike a fine balance between “must haves” and “nice to haves,” without impacting quality.

Our ONEsolution approach

ONEsolution combines and evolves the most effective ideas behind integrated project delivery. A ONEsolution project starts with one united design-build team, and supplies that team with the tools, the business insights, and the culture necessary for success. As a result, projects move faster, cost less, and deliver lasting results.

To meet the Tuffy’s brief, we leveraged several core ONEsolution functions, including:

Early team integration

We identified which trade partners would have the greatest impact on our timeline, and we onboarded those partners as a first priority. Their expert feedback during the design phase helped to reduce wasted effort, ensuring that we met critical project milestones before winter conditions arrived.

Project chartering

We worked closely with the project owners at Tuffy’s to establish a project charter using a strategy focused on trust and communication. Tools like The Last PlannerⓇ System supported that strategy. Team members used these tools to understand their contribution to the overall project schedule and to participate in a culture of shared accountability, which impacted every aspect of the project from design through construction and startup.

Parallel design and construction activities

When the project began, we had relatively little time to spare before winter arrived in Minnesota, bringing temperatures as low as -20F. In order to design, build, and heat the shell structure in time, we pulled construction activities up. For example, we worked with our steel and precast trade partners to develop fabrication drawings in parallel with design drawings. This decision allowed for shallower foundations, which reduced the volume of earth we would need to move and the volume of engineered fill required. As a result, we not only accelerated our timeline, sparing workers from the cold—we also saved millions.

Zero-based scope (ZBS) and target value delivery (TVD)

Success depended largely on our team’s vigilance in maintaining the overall budget. We started by establishing a firm project value using ZBS techniques, explained below. Next, we leveraged the principles of TVD to avoid exceeding that value as design and construction progressed.

Backed by these tools, our team delivered the advanced, hyper-flexible facility that Tuffy’s required, on their schedule—for $800,000 less than expected.

Zero-based scope

What is zero-based scope?

The idea behind zero-based scope (ZBS) is to right-size projected costs according to the base requirements of a project.

Unlike more traditional scoping exercises that start with a budget and work backwards, a ZBS technique—as its name suggests—starts from zero and builds the project scope from there. Every factor that adds to the scope must be assessed for its necessity, relevance, and alignment with the project’s established business goals.

How we applied a zero-based scope technique to the Tuffy’s project:

We begin every project with a chartering phase, in which we work with owners to understand their business drivers and to establish the project’s conditions of satisfaction.

In this case, our chartering phase helped us to define two key facility requirements:

- Safety: Tuffy’s sought to differentiate themselves by offering clients a standard of safety and food sanitation rarely seen in pet treat manufacturing. As a core component of their business plan, this aspect was a top priority for our design-build team.

- Hyper-flexibility: To ensure that their facility would retain its value long into the future while attracting a diverse and innovative clientele, our design-build team was equally focused on maximizing flexibility and internal configurability.

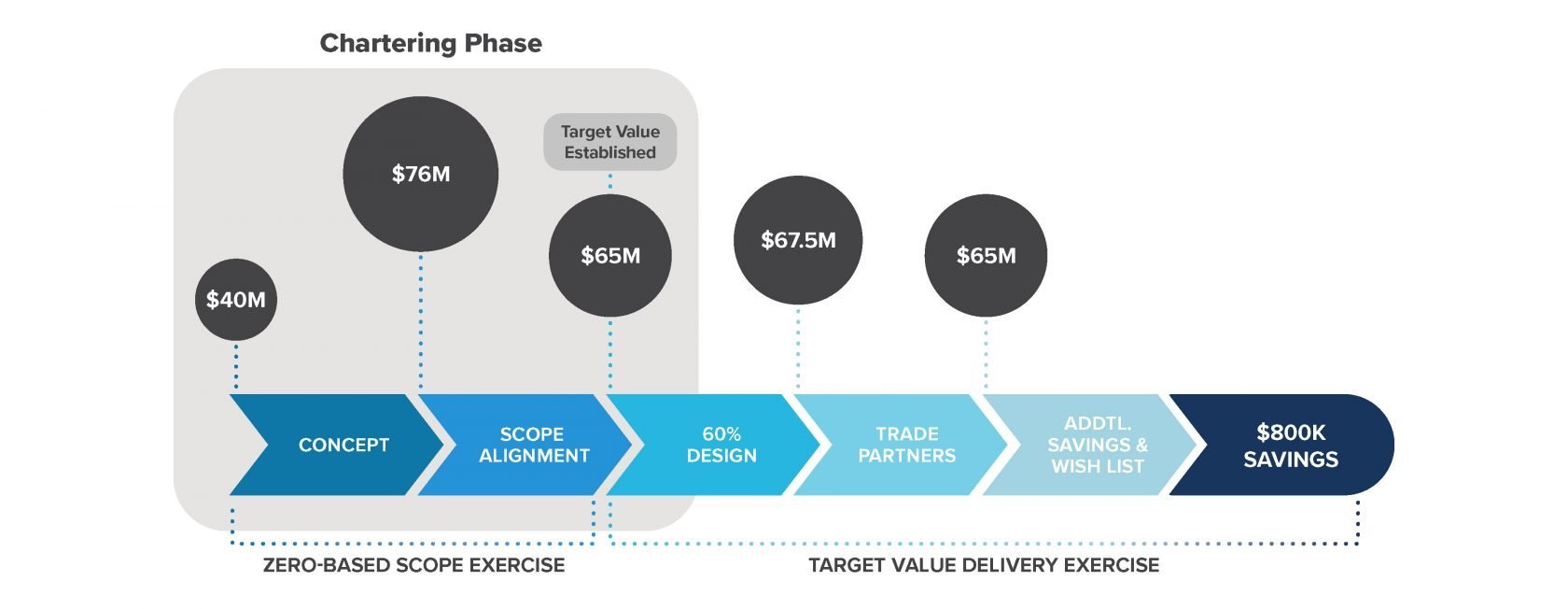

Initially, the Tuffy’s team hoped to invest $40M to satisfy these requirements and complete the project.

To test the realism of this target cost, we started from zero and began to build a “blue sky” project scope. At this stage, nothing was off the table—our project scope accommodated both Tuffy’s key “must haves” and every “nice to have” element on their wish list.

We valued this complete design concept at $76M. Our next task was to find a realistic middle ground between Tuffy’s aspirational cost on the low end, and the cost of a blue-sky design at the high end.

This is where the rigor of ZBS paid off. We pressure tested our assumptions against the project charter, using the client’s business case as context. Through this lens, we could clearly identify which elements of the project scope would directly impact Tuffy’s priorities of safety and flexibility. This confirmed which elements were indeed “must haves.” That left us with a set of “nice to have” elements which could be revised, removed, or reconfigured until we met the business case with a target value of $65M.

How ONEsolution supported our zero-based scope technique:

Our emphasis on early team integration meant that we could rely on the combined expertise of designers, construction managers, equipment vendors, and project owners to help us scope the project with certainty.

Target value delivery

What is target value delivery?:

Put simply, the goal of target value delivery (TVD) is to continuously track costs and find offsets in order to deliver a high-quality facility within the value determined in the ZBS phase. Ultimately, TVD approaches cost as a design constraint rather than an outcome of design.

How we applied target value delivery to the Tuffy’s project:

On a project governed by TVD, the cardinal rule is that the project team must never exceed the target value. That was on our minds as we progressed from big-picture concepting into detailed design work. Once 60% of those detailed designs were complete, our projected costs had increased to $67.5M, or $2.5M over the target value.

Our trade partners helped us address this discrepancy. Because we had integrated them into the team early on, we could rely on their familiarity with Tuffy’s business goals. Working together, we uncovered creative and reliable ways to re-align our design with the $65M target value.

We tracked each of these design decisions in a variance log, which functioned as a wish list for the project team. Over time, as the budget allowed, we pulled features from the wish list and added them back into the project scope—but only after meeting all base facility requirements first.

In this way, we were able to deliver the ultra-safe, hyper-flexible facility that Tuffy’s needed, including several of their “nice to have” features, for $800,000 below the target value.

The facility’s packaging space is a good example of how this worked in practice. Initially, we had planned to hang metal ductwork in that space, which would create a lot of flat surfaces. Where there are flat surfaces, there’s dust—and there’s someone paid to clean away that dust, particularly in a space where food safety is a priority. If we could reduce the need for this cleaning protocol, we could in turn reduce the facility cost. That’s when our team suggested that Tuffy’s consider a product called a duct sock.

The duct sock inflates while HVAC is running and deflates when it isn’t, which prevents dust from accumulating. What’s more, the dust sock was significantly less expensive than the metal ductwork initially scoped. By steering Tuffy’s towards this decision, we helped them to meet their charter requirements while reducing their costs at the same time—a triumph of TVD.

Core requirements vs. “blue sky” wishes

A great TVD strategy drives value so efficiently that, as the project evolves, owners can start pulling from their wish list while staying “in scope.”

A core requirement for Tuffy’s: A safety strategy that borrows from biopharma

To enhance Tuffy’s segregation and quality control strategies, we designed a hard boundary between pre-kill and post-kill processing zones. Each zone features its own eating areas and bathrooms—even separate parking lots. Duplicating these amenities eliminates repeated gowning and decontamination steps while better controlling risk across the whole plant.

By identifying this level of safety and sanitation as a priority early in the project’s development, we were able to build an accurate project scope and focus our design effort where it mattered most.

A wish for Tuffy’s: A second floor

As we refined our project scope to align with the target value, the notion of adding a floor above the facility’s administrative area came up for consideration. We consulted closely with Tuffy’s, ultimately determining that the second floor was not mission-critical, and did not contribute to either of the project’s twin priorities (safety and flexibility).

Rather than eliminate the option, though, we tracked it in our variance log. As the project progressed and we found more economies, we were able to add this feature back into the design without exceeding our budgetary threshold.

How ONEsolution supported our target value delivery approach:

Because we had established a well-functioning, integrated team, we were able to release design packages early and take full advantage of offsite fabrication.

This approach offered multiple advantages. It reduced the number of people working on-site, which made social distancing possible and helped us to protect the health and safety of our team throughout the COVID-19 pandemic.

This approach also reduced our on-site labor costs and improved overall efficiencies, which in turn helped us to stay within the target value while systematically adding to the project’s scope. For example, we brought our steel fabricators to the design table early, leveraging their expertise to refine and expedite the critical-path delivery of core structural elements. We did the same with the precaster responsible for making many of the facility’s interior walls. These early team integrations cut several weeks from our schedule and ensured that facility elements arriving from offsite shops were exactly what we needed—no more, no less, and no rework required.

RESULTS: A safe, efficient, hyper-flexible pet treat facility without compromising on quality or capacity

The new Tuffy’s facility, which expands the company’s semi-moist pet treat capacity by 500%, is a model of safe, efficient and hyper-flexible food manufacturing.

It’s also a model of how a Zero-Based Scope, paired with a diligent Target Value Delivery approach, can support ambitious business goals without compromising on quality or capacity.

Our ONEsolution team applied these tools to maintain cost certainty from start to finish, ultimately delivering the new facility for $800,000 below the target cost, on a fast-tracked schedule, and with several features not originally included in the scope. Based on the strength of this project, we’re now working with Tuffy’s on further expansions.