Integrated, successful teams

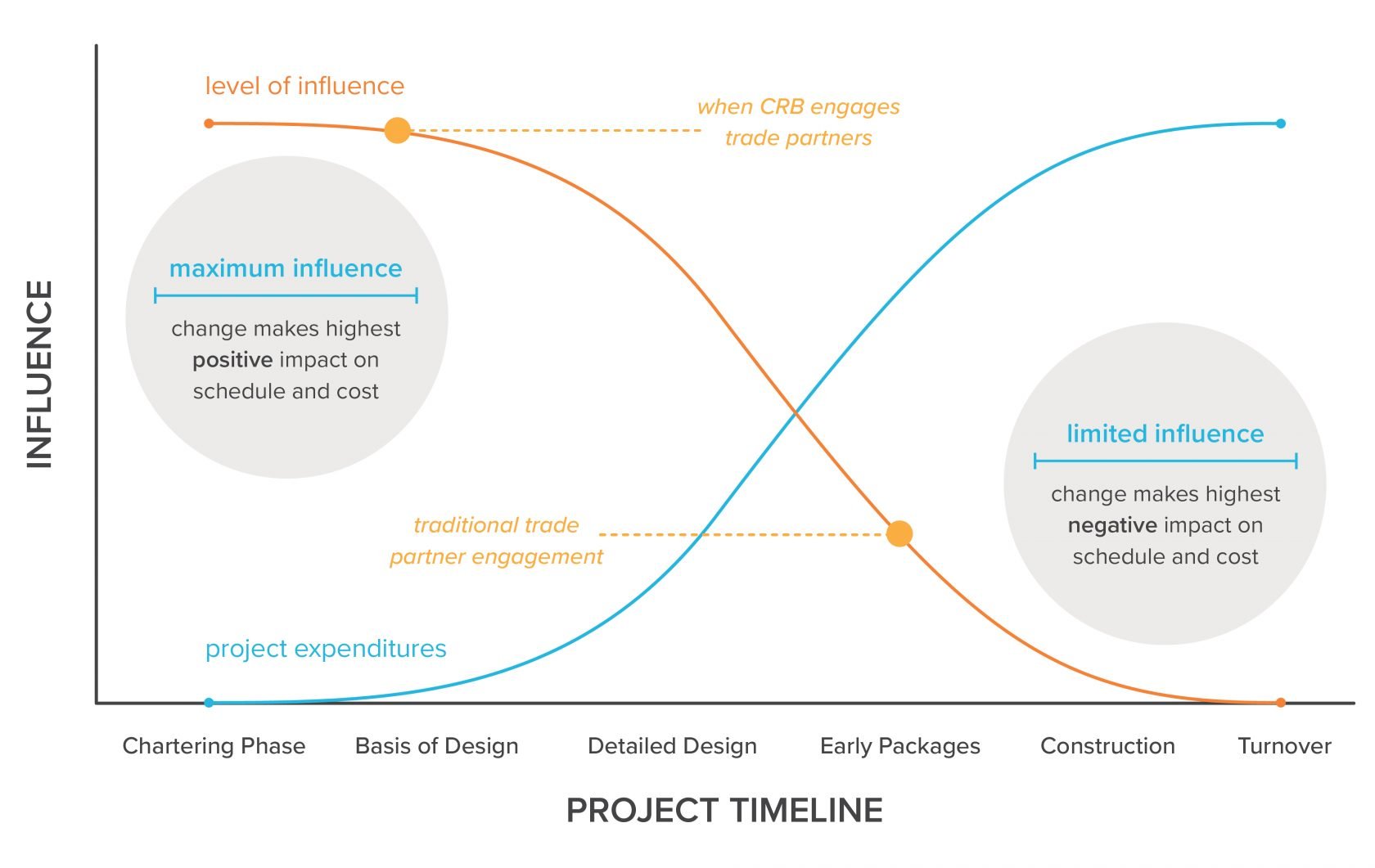

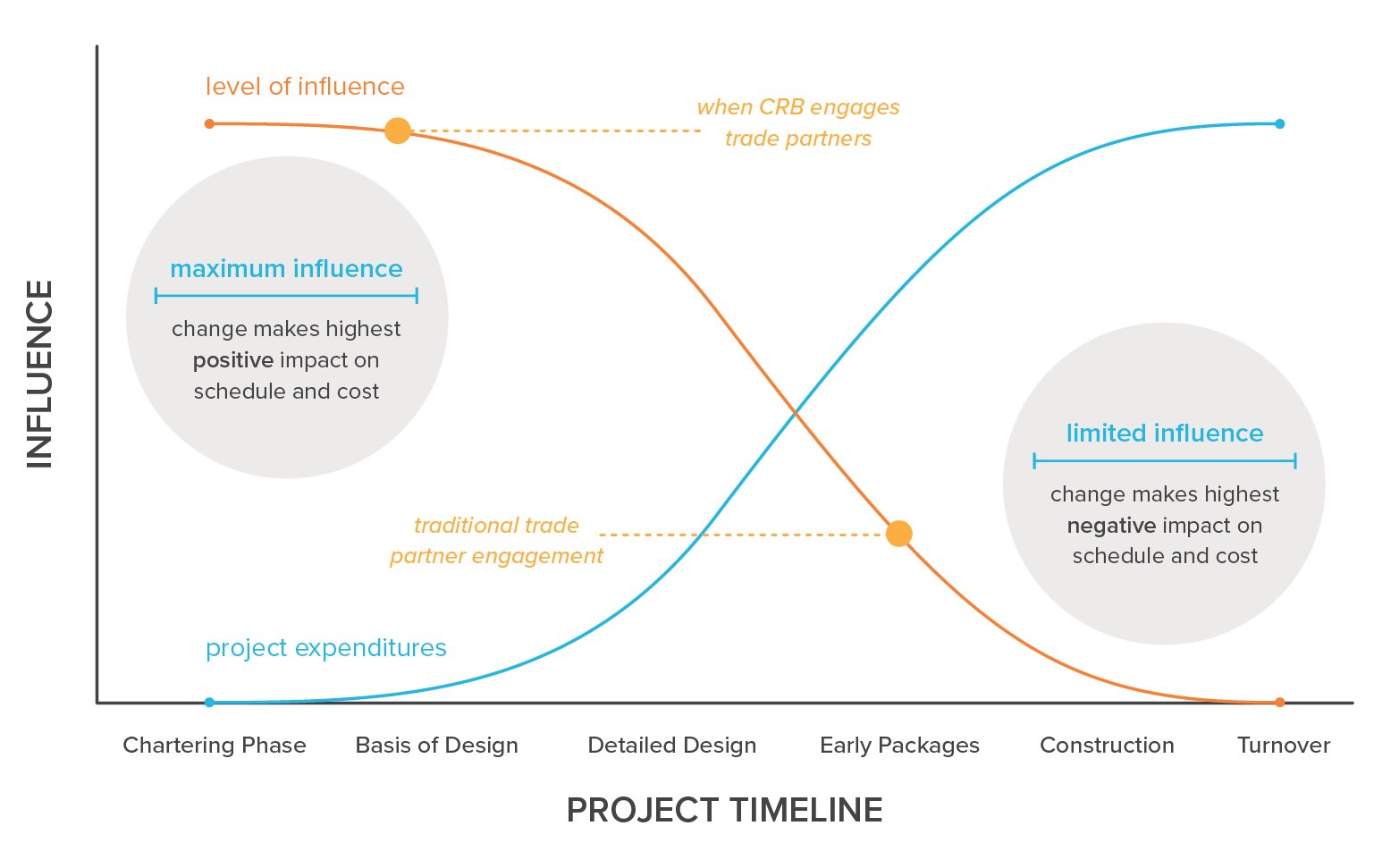

Find out more about ONEsolution, CRB's integrated project delivery method.Today’s supply chain issues, labor shortages and construction cost inflation have made it imperative that projects operate with unprecedented efficiency. The relationship between the design, construction management team, and the subcontractors can be rife with inefficiencies and breakdowns. Establishing strategic relationships with key trade partners early on has been shown to significantly improve project cost and schedule certainty.

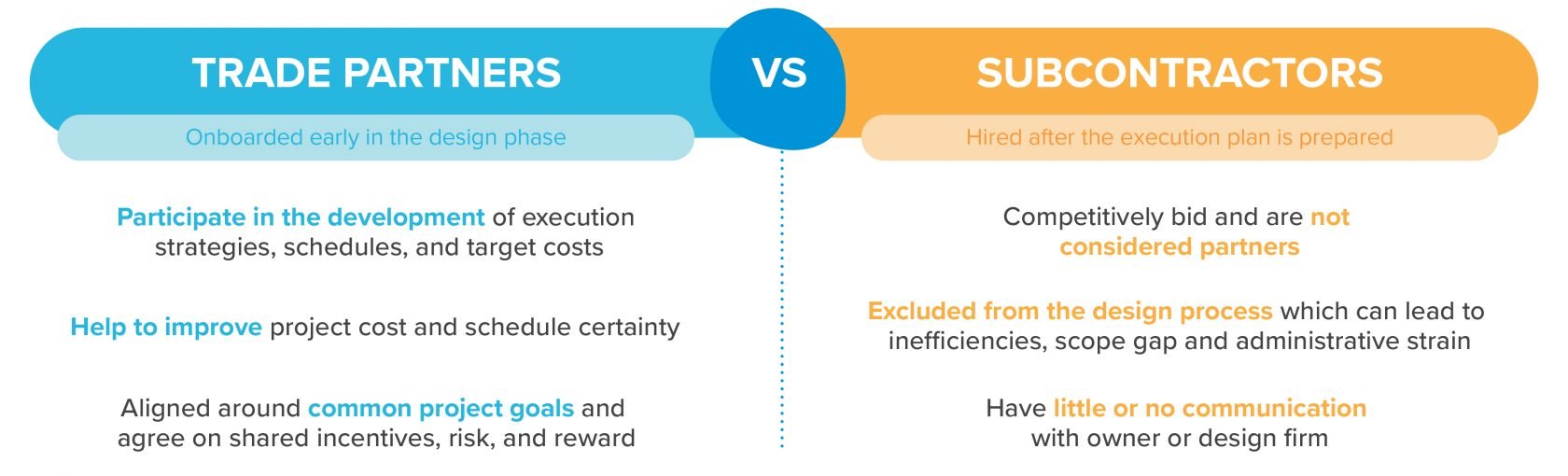

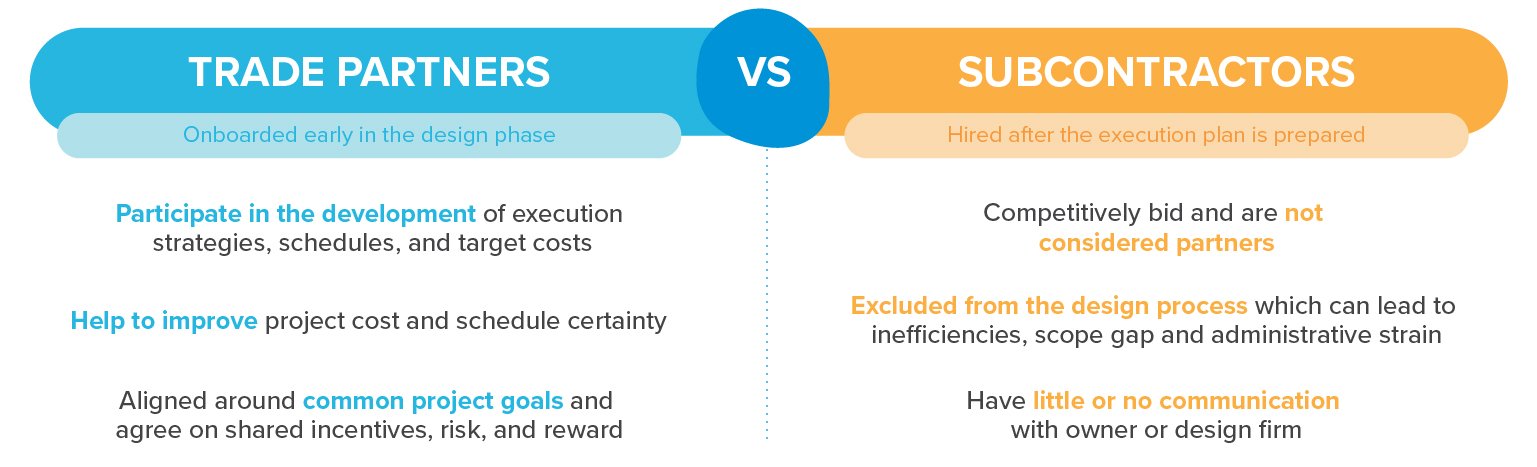

What’s the difference between a trade partner and a subcontractor?

The main difference between trade partners and subcontractors is that trade partners are onboarded early in the design phase to participate in the development of execution strategies, schedules, and target costs; while subcontractors are hired at a later stage, after the execution plan is prepared.

How do contracts and delivery methods impact trade partner relationships?

Given that work sequences, timelines and budgets rely on coordinated efforts between multiple companies, the contract and selected project delivery method have a significant role to play in setting teams up for success. The three most common project delivery methods include:

Design-bid-build

For decades, this method has been the norm: an agency or owner contracts with separate entities for the design and construction of a project. They put out a request for proposal (RFP), and a design team produces bidding documents, including drawings and technical specifications. In the process of responding to the RFP, the general contractors send the documents to multiple subcontractors per trade. The subcontractors and general contractor develop their pricing in a compressed time frame, solely based on the parameters outlined in these documents, and with little or no communication with the owner or design firm. Understandably, the bids usually contain multiple clarifications and exclusions. Subsequently, contract administration is subjected to multiple requests for information (RFI), change orders, cost overruns, and schedule delays. The process isn’t designed for ongoing communication up or downstream, nor does it usually yield projects on time or on budget – so much so that this has become a well-worn joke about construction as a whole.

Design-build

Rather than the owner managing separate contracts with both the designers and contractors, in this method, the owner manages a single contract with a design-build entity. The single point of responsibility contract, typically contractor-led, reduces risk and cost by providing one point of contact to the owner, and allowing for some overlap of design and build processes. However, subcontractors are typically still competitively bid and are not considered partners. As a result, trades don’t participate in the design process, and opportunities to leverage their industry knowledge are missed. There’s less accountability from the subcontractors, and therefore a greater potential for scope gap and administrative strain from the resulting change orders and RFIs. While still an improved process over design-bid-build delivery, this process still struggles to provide early cost and schedule certainty.

Integrated project delivery

Integrated project delivery (IPD) is focused on forming a high-performing, collaborative team made up of the owner, CM or GC, architect, engineers, and major trade partners. This team is formed early in the project life cycle, based on an agreement where governance and incentives, risk, and reward are shared. A project chartering phase is typically undertaken to align the team around common project goals, including maximum allowable cost, schedule, and Conditions of Satisfaction (CoS). Target Value Delivery and shared risk & reward are utilized to incentivize teams to collaboratively make decisions within the common set of project goals and CoS. IPD does require more up-front involvement from the owner than design-build, but for many owners, the ability to influence the end product, reduction in change orders, and improved cost and schedule certainty is worth the effort. Most importantly, the collaborative nature of IPD projects results in significantly less conflict and a much better project experience for all team members. This is a reinforcing cycle that continuously improves the performance of IPD teams.

What are the benefits of including trade partners on your project team?

For those new to the concept, including truly integrated trade partners requires a reframing of mindsets and processes from traditional project delivery methods. However, early investment and integration of trade partner expertise benefits all stakeholders. Here are three key ways trade partners can be a major asset to your project’s success.

Trade partners work with high-performing teams toward shared goals

A typical capital project has at least a dozen subcontractors. Their only common goal is delivering on their low bid, and their focus is on completing their scope of work at the lowest cost possible. They have little to no concern about the owner’s overall goal, conditions of satisfaction (CoS), or other project team members. Enormous amounts of time and energy are expended in responding to RFI’s, change order negotiation, punch lists, and arguing about the root cause of schedule delays. An IPD project forms a high-performing team that is focused on common goals and CoS. This is typically reinforced by the major players participating in a shared risk and reward strategy where success and failure are shared amongst the team. The participants collaborate to ensure that the execution of their scope supports the overall project goals, considers the impact on their peers, and is consistent with the CoS. When problems arise, the group tackles them with a holistic view rather than spending time and resources identifying the party at fault. Time that would be spent in conflict resolution can instead be utilized in collaborating on optimizing safety, quality, cost, and schedule.

Collaboration with trade partners increases efficiency and maximizes value

Including trade partners at the planning table means they can lend their expertise to the design and execution plans while they are still being developed. Under traditional project delivery methods, the project scope and specifications are developed by the design team with no input from the people that will be responsible for performing the work. If a subcontractor identifies an improvement to the design or specifications, they have to communicate this via a bureaucratic RFI process. Due to this occurring after the detailed design effort is complete, there is typically little incentive for the designer to incur the cost and delay of revisions to their design.

Early trade partner involvement, in combination with lean tools such as Target Value Delivery and Last Planner System, enables teams to gain alignment on scope, cost, schedule and execution plan early in the project life schedule. This process is inherent to target value delivery success, a management practice used to deliver projects within a fixed budget, while meeting the operational needs and values of the client. The upfront investment is returned many times over via early cost certainty, fewer RFI’s and change orders, minimal punch lists and improved project execution.

Early alignment with trade partners accelerates project schedules

A major benefit of onboarding trade partners early in the project lifecycle is schedule acceleration. A typical IPD project shaves months off the schedule compared to a design-bid-build or even a design-build project. In addition to eliminating weeks of procurement time between the end of detailed design and the start of construction, there are numerous other areas that benefit the schedule.

At CRB, early trade partner involvement typically involves participation in the modeling effort. Rather than redrawing the designers’ work, trade partners work under the direction of the professional of record to develop optimized fabrication level drawings. This enables earlier model releases and more flexibility in work sequencing. Trade partners can get to work on prefabricated elements while the core & shell is being constructed, allowing multiple work sequences to occur simultaneously without teams waiting for free space in which to work.

Significant schedule acceleration can be gained by allowing trade partners to provide input into the procurement processes. Their market knowledge of cost and lead times associated with equipment and materials allows for project specifications to be optimized and eliminates the time-consuming process of evaluating alternatives. Early sightlines into the project specs allow trade partners to order long lead equipment and materials prior to the design being finished. It also means they can secure labor availability and coordinate teams that are ready to hit the ground running as they are needed.

The ability of a collaborative, high-performing team to proactively identify challenges, quickly identify the best decision, and rapidly implement mitigation measures is invaluable in maintaining project schedules. With today’s supply chain challenges, this is more important than ever.

Understanding the value of trade partners

The benefits of trade partnerships are pretty compelling, so why don’t all projects implement this approach? Why would clients choose to lose out on the opportunity to engage trade partners that were committed to their overall project goals and CoS?

We suspect there is a false sense of security built into the bidding process. Traditional procurement practices focus on competitive bids, that are based on interpretations of the design drawings and unrealistic schedules. This process yields bids with numerous clarifications and exclusions that result in numerous change orders, schedule delays, and cost overruns. Owners, for their part, need to appreciate that the lowest bid seldom equals the highest value, and that the bid is seldom reflective of the end cost.

Instead, early investment in the expertise of trade partners can help to anticipate and prevent costly obstacles and delays. With trade partners incorporated as part of a high-performing team aligned around common project goals and CoS, teams are able to identify creative ways to achieve cost targets and shave months off project timelines.

At CRB, we support our clients in achieving safety, quality, cost certainty and speed to market with fully integrated, high-performing teams. Together, we’re building a new paradigm for our industry, where lean principles and a collaborative spirit allow for more successful project execution and a better project experience.