T. Marzetti

Read More

Updated product wheel increases throughput by $9.7 million annually

An existing client came to CRB with an operational challenge:

Could CRB’s consulting team develop a new, optimized product wheel for next year’s production?

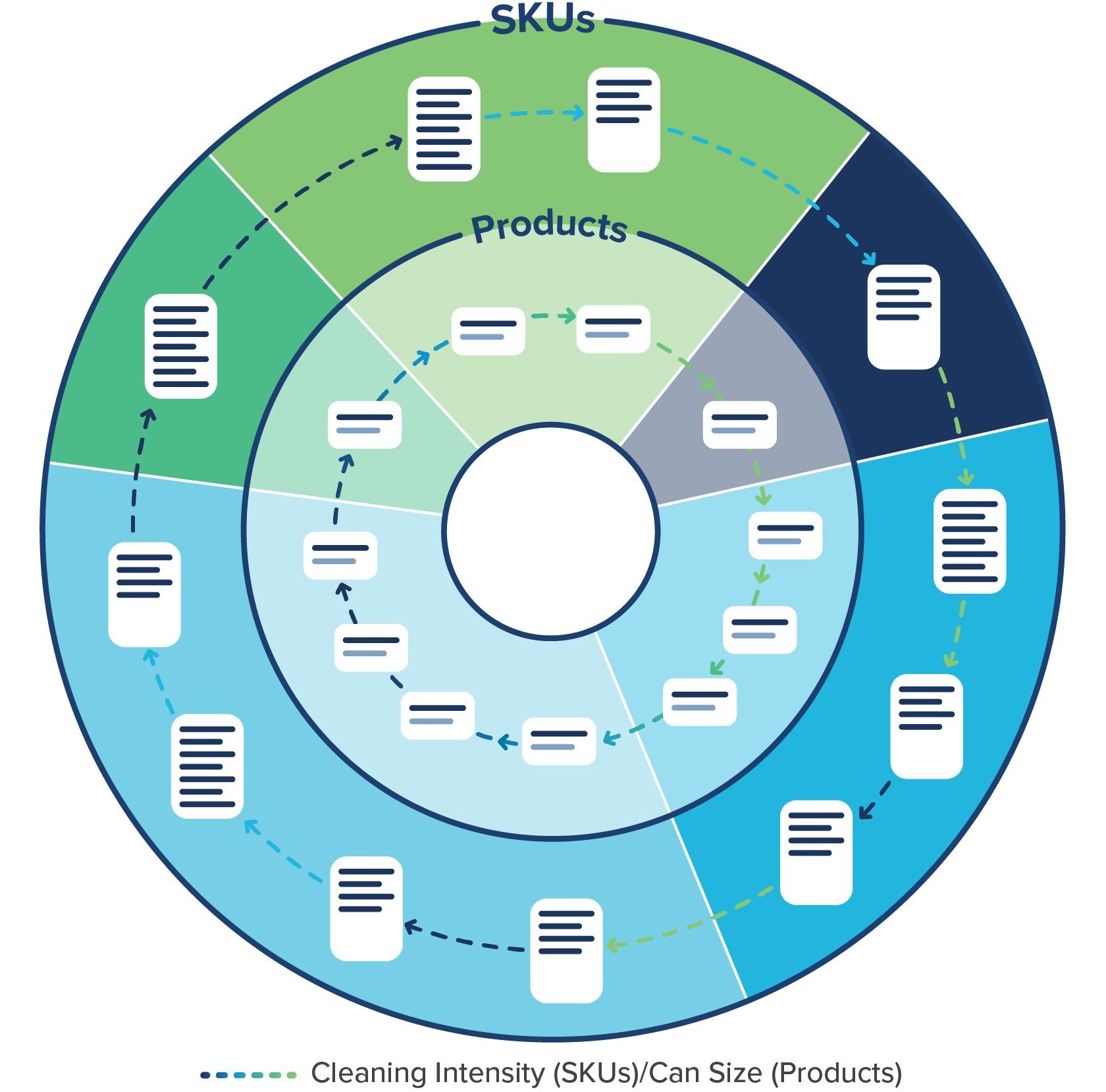

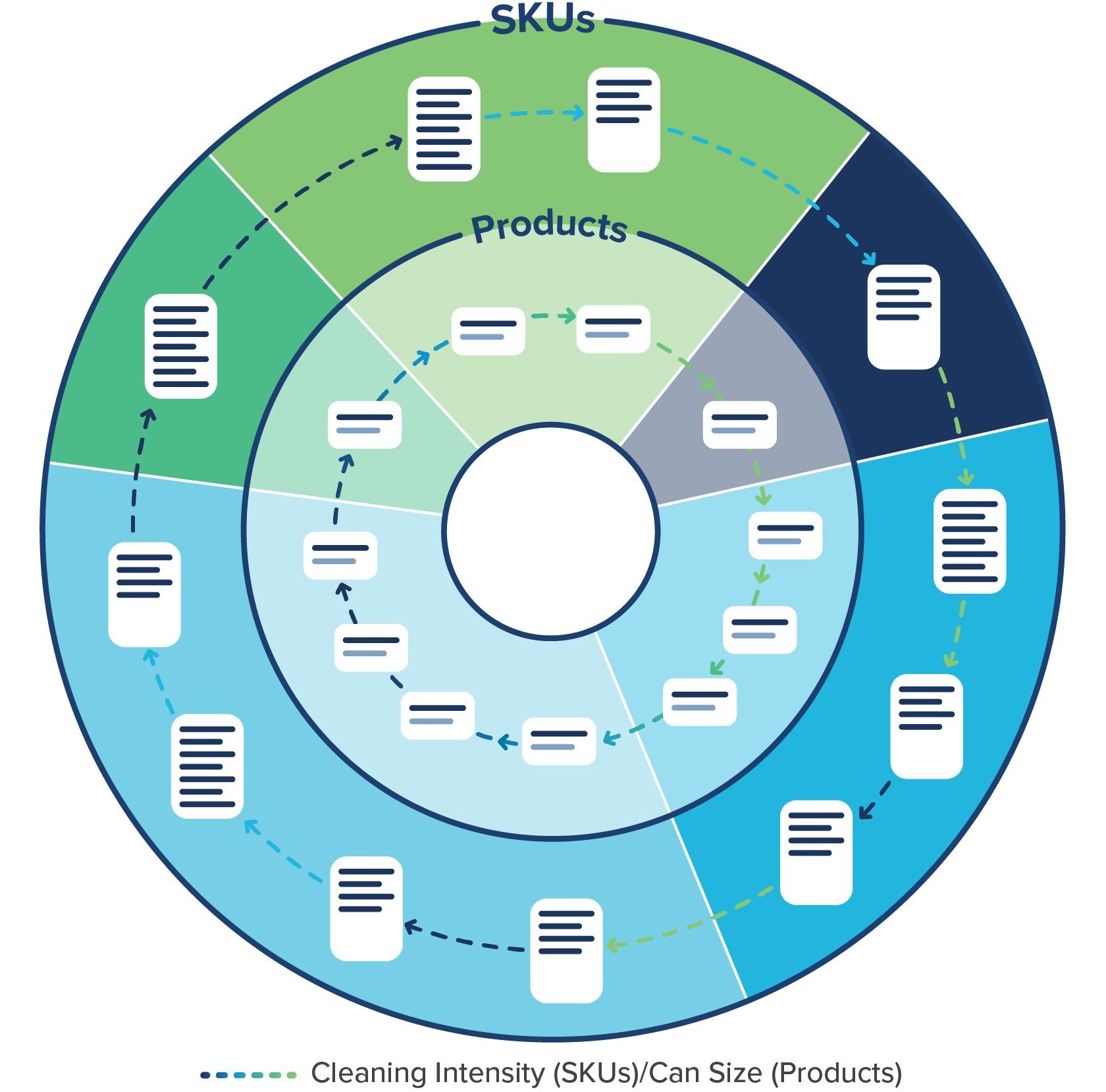

This nutritional powder manufacturer was running approximately 200 different product and packaging combinations in its facility with an outdated and inefficient product wheel. Our client sought an improved multi-product campaign wheel that would allow the manufacturing team to maximize materials and operations with a holistic schedule identifying which products and volumes should be run and when.

What is a product wheel, and how does it support efficient manufacturing processes?

It is a common manufacturing practice to group and run several batches of the same product family, or SKUs consecutively in a campaigned fashion to reduce changeovers and improve manufacturing efficiencies. A product wheel is a big-picture strategic schedule for this process supporting lean manufacturing practices. A good production wheel and campaigning strategy is necessary to reduce waste and non-value-added activities, though some non-value-added activities are essential, e.g., cleaning.

Planning and creating a new product wheel

Our team performed a comprehensive study to evaluate the client’s product routing, run rates, changeover durations in dryers and packaging lines, and flushing losses.

The study revealed multiple opportunities for production improvements. CRB delivered a new product wheel for all 200 product and packaging combinations that specified which week each should be produced. This new product wheel was easy to implement. It also provided flexibility to accommodate future products and SKUs effectively.

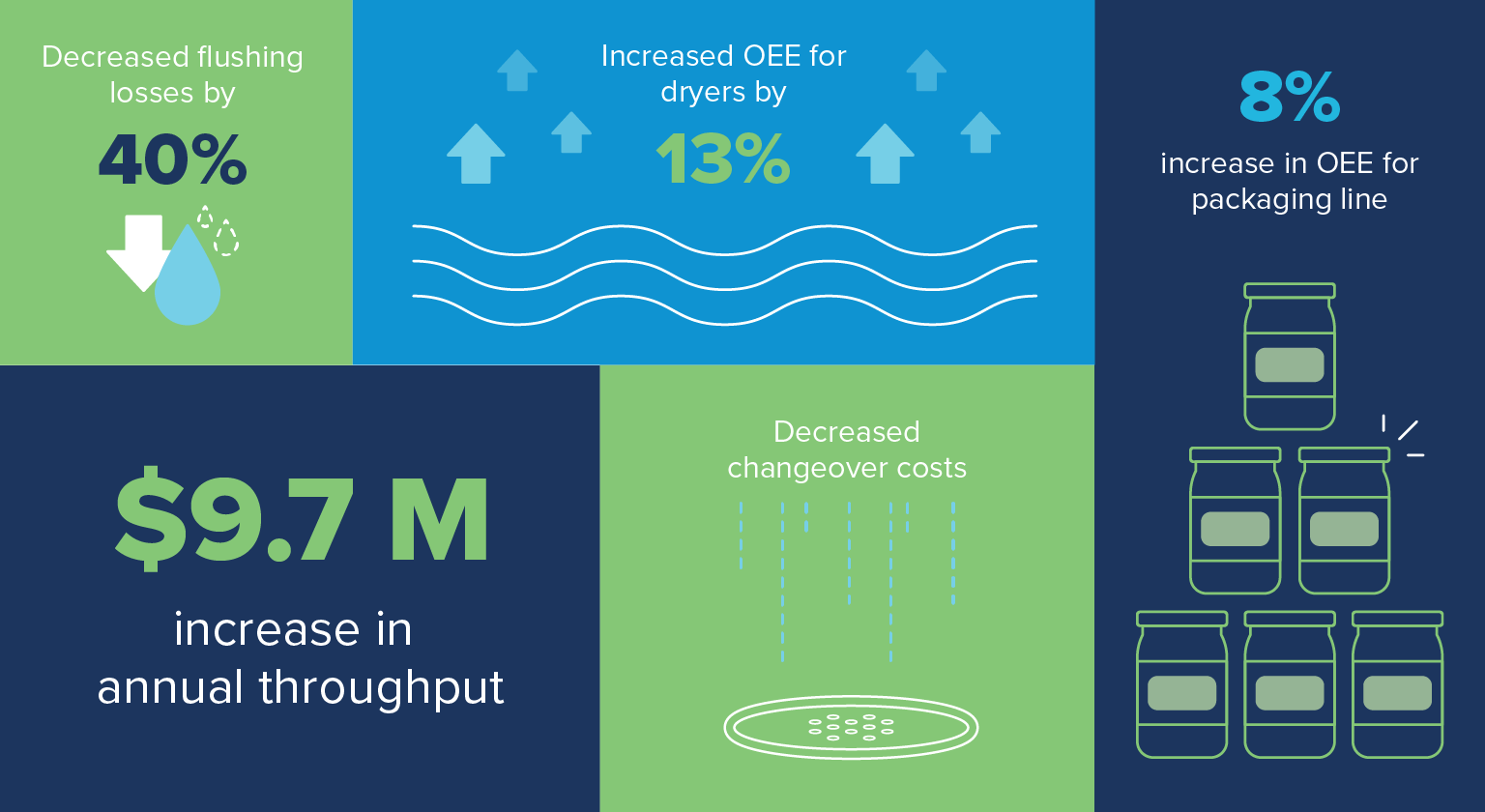

The new product wheel was compared against the old scheduling philosophy to measure changes in overall equipment effectiveness (OEE) for dryers and packaging lines, total changeover duration and flushing losses.

What is overall equipment effectiveness (OEE)

OEE is a measure of how well the equipment (or lines) are utilized. In other words, % of manufacturing time that is truly productive. How to find your OEE:

- OEE = availability x performance x quality

- Availability = total time – downtime

- Performance = actual throughput / theoretical throughput

- Quality = output / (output + scrap)

The benefits of an optimized product wheel

The client’s new product schedule decreased cleaning requirements, thereby reducing the flushing losses. The time freed up by eliminating or reducing cleaning intensity allowed for packaging lines and dryers to be more productive. Our consulting team’s study resulted in:

- Decreased flushing losses by 40%

- Increased OEE for dryers by 13%

- Increased OEE for packaging line by 8%

- Decreased changeover costs

- Increased throughput by $9.7 MM annually

Niranjan Kulkarni, PhD, walks through the business benefits and importance of regularly updating your food manufacturing product wheel.

When to introduce a product wheel in your operations?

Any manufacturer running multiple (more than one) products without dedicated lines could benefit from a product wheel. Because there are only a finite number of hours you can manufacture in a day, week or year, a smart changeover strategy is critical to maximize production when running multiple products and reduce non-value-add activities.

A classic product wheel example is progressing a product family from vanilla to strawberry, and then to chocolate, aligning the flavors based on which will overpower the previous. If these run in a different order, your CIP would need to be more intense, wasting additional time and resources.

Also consider that today’s food market is much more complicated, with customer preferences like gluten-free, dairy-free, and non-GMO dominating product families. These sensitive variations require a more rigorous cleaning and changeover strategy to ensure your manufacturing operations are optimized.

Site-specific is key

Product wheels need to be developed specifically for each site. Even if you are running the exact same products at each site, the variations that exist can cause inefficiencies and warrant a new product wheel.

Factors to consider when product wheel planning

- Bottlenecks. Does a bottleneck frequently move as a function of running different product families and SKUs? How would your bottleneck be impacted by this new strategy?

- Product count. How many product families and SKUs are you working with? Does that change seasonally?

- Resource availability. Is a particular product or packaging manually intensive? If your schedule changes, will it cause a spike in labor needs for a certain part of the day or week? As for material availability. when are your fresh foods available? How often does that change?

How frequently should you update a product wheel?

Our Operations Improvement team recommends you reevaluate existing product campaigning strategies when new product families or SKUs are added to production, when new technologies are implemented, or when your workflow changes.

How do you know it will work?

To determine if a product wheel works, you can test it in the real world, or you can test it in a computer simulation.

- Real-world: Implement the heuristic and see if and how it works in real life. The downside is that if the new schedule hits a hiccup, you risk manufacturing downtime or delays as you troubleshoot.

- Simulation: Our preferred method is to create and test the new product wheel in a simulation. This way, you can experiment and make small tweaks to improve outcomes. A simulation allows you to see which efficiencies are gained and by how much. You could also use the simulation to identify if an existing bottleneck moves or a new one results from the changes.

Creating a product wheel is only the start. Ensuring your scheduling and planning team will actually use it is a major factor in its effectiveness. Your team must understand the new plan to stick to it. This may require some changes to your ERP (enterprise resource planning) system or change management may be needed to realize the full potential of this new plan.

Ready to plan your new product wheel schedule?

Process inefficiencies can occur with seemingly small changes, which escalate to wasted product, underutilized equipment and expensive bottlenecks over time. It’s essential for manufacturers to regularly examine operational processes to catch inefficiencies and continually reduce operating costs. The case study above is just one of the many ways our Lean Six Sigma certified, Operations Improvement consulting team has helped our clients increase capacity and achieve leaner manufacturing operations. When you are ready to start planning a new product wheel, our team can help.

Where are you wasting time, product and money? Our team of consultants can tell you. Let’s talk.