Dairy has long been a powerhouse consumer category. After all, there is a reason why grocery stores tuck the eggs and milk in the far corner—customers will reliably make the trek to scoop up these staples. Like so many other industries, the dairy industry experienced significant shifts during the pandemic—all to its advantage. Milk dollar sales took off, rising 7.8% during the 52 weeks ending Sept. 6, 2020. As consumers reached into the freezer for some comfort food, ice cream dollar sales spiked 13.4% in the same time period. Butter is experiencing a renaissance—in part due to revised health advice—and is spreading out with gourmet finishing butters (e.g. black truffle or garlic parmesan).

The long-range results of this shift in buying habits aren’t known yet, but in the meantime, we are seeing a separate consumer trend in value-added dairy milk offerings—such as those touting additional nutritional or performance benefits (e.g. probiotics or added protein). Chocolate milk is trending as a post-workout recovery drink. Specialty flavors and innovative shelf-stable products are also encouraging consumers to stock up on dairy products.

Behind the scenes, the dairy industry is constantly improving. Advances in processing methods are yielding higher quality products. New processing methods can help reduce waste and increase milk production and process efficiency. For example, the implementation of improved mix-proof valves is supporting expanded automation, increased flexibility, and increased efficiency. New and advanced approaches to filtration are helping manufacturers increase their protein content and are driving improved control of solids.

In all, the dairy industry is experiencing a period of growth and innovation. In order to leverage these shifts in a competitive and increasingly diversified market, dairy processors need a flexible and innovative approach to facility planning and operating.

Dairy products

Milk contains multiple product types, alongside other equally important dairy products:

- Fluid milk products

- Flavored milk and eggnog

- Traditional and Greek yogurt

- Butter and dairy spreads

- Cheeses and related cheese products

- Sour cream, cream cheese, and cottage cheese

- Milk and whey powder

- Ice cream

- Whey processing

- Condensed milk

All these products begin with a single ingredient: fresh farm milk. Before it transforms into any of the products mentioned above, it goes through several steps of processing to meet quality and regulatory requirements.

Regulatory requirements

State and Federal Regulations and Inspections

Regulations address the production, handling, processing, packaging, storage, and distribution of milk. Historically, the dairy industry has been one of the most regulated food industries. Why? Milk and milk products are prone to growing microorganisms— including pathogens such as E. coli, salmonella, and listeria—if left unchecked. The goal of state and federal dairy laws is therefore to protect the quality of the products and the health of the consumer. If a dairy plant fails to meet its legal local or national obligations, the results can be costly and damage their reputation.

Pasteurized Milk Ordinance

The FDA established a set of minimum standards and requirements for regulating the production, processing, and packaging of Grade A dairy products. These standards are known as the Pasteurized Milk Ordinance (PMO). Dairy industry, government agencies, and academic representatives collaborate to write the regulations in the PMO, which they revise every two years.

Steps of milk production and dairy processing

Raw receiving

Processors receive raw milk in insulated road tankers. Once the dairy product arrives at the dairy, the quality team runs tests to ensure it meets appropriate standards. Common tests include smell, temperature, and various lab tests.

Raw storage

Large vertical silo tanks store untreated raw milk. At this stage, operators must carefully monitor two key variables: the temperature inside the silo and the time held in the tank. An optimized combination of the number and size of tanks will help processors maintain production rates and minimize waste

Batching operations

Batching is a rapid process combining liquid and dry ingredients in the proper ratios to meet recipe and batch size demands. It is used in many products such as ice cream, chocolate milk, yogurt, and eggnog. Batching operations typically fall into sequential load cell systems or simultaneous, meter-based systems.

Pasteurization

Pasteurization is the process of using heat to destroy pathogens to improve food safety. Importantly, pasteurization forms the regulated boundary between the raw and pasteurized sides of the process. The most common method of dairy pasteurization in the United States is High Temperature Short Time (HTST), which is a continuous process that processes milk efficiently.

Separation and clarification

Separating skim milk from cream is a fundamental process in the dairy lifecycle. The separation process uses centrifugal forces to separate the cream from the skim so that they can be used in other products. Clarifiers throw particles such as sediment, somatic cells, and some bacteria to the outside for disposal.

Standardization

Standardization is the process of adjusting the fat content of milk to a specified value. It is an important mechanism to deliver a uniform product to consumers and helps to ensure economics in production. Standardization typically occurs via one of these two methods:

- Continuous standardization – Blends cream and skim via monitoring the ingredient and product characteristics and adjusting the flows as required to meet the process requirements.

- Batch standardization – After separation, combine calculated volumes of cream and skim into batch tanks under continuous agitation. Operators confirm product characteristics via lab testing and adjust as required. This method is uncommon in modern dairies unless the product requires additional ingredients.

Homogenization

Homogenization breaks down fat globules to prevent the formation of a cream layer. A homogenizer forces hot milk at high pressure through a narrow slit, breaking up the fat globules so they cannot recombine later.

Culture and fermentation operations

Producers of cultured milk products, such as yogurt and cheese, rely on bacteria cultures (also known as ‘starters’) to control the acidity, consistency, flavor, and aroma of the product.

Nowadays, many dairies buy ready-mix cultures directly from laboratories offering special cultures for specific products. These commercial cultures are available in deep-frozen, freeze-dried, and liquid forms. Manufacturing a starter is one of the most important steps in the dairy process, and the safety and hygiene of this process are extremely important.

The process can be broken down into the following steps:

- Culture prep and storage – The first step in manufacturing a starter is processing the medium. The medium is heated and held at temperature, then cooled to the required inoculation temperature. The target temperature differs according to the product. Once the medium reaches the correct temperature, inoculation can begin.

- Culture inoculation – During inoculation, a quantity of specific bacteria is transferred to the medium, either manually or automatically.

- Fermentation process – After completing the inoculation process, the product moves into fermentation. When bacteria reach the target temperature, they begin to reproduce very rapidly and ferment into the final product. After achieving the desired flavor and aroma, the cultured milk must be cooled quickly to stop the fermentation process. Most fermentation processes will also begin agitating the cultured product at this processing step.

Pasteurized storage

While pasteurization kills disease-causing bacteria and extends shelf life, even pasteurized milk can quickly spoil and cause foodborne illness if not handled properly. Refrigeration is a critical factor in ensuring the safety of milk: the warmer the milk, the more rapidly bacteria grow and multiply. Common storage temperatures are 36°F to 38°F (2°C to 3°C).

Filling and packaging

- Filling – Once in the processing line, milk can be transferred into many different types of packages including cartons, glass, pouches, bottles and others.

- Packaging –Packaging systems organize product containers into easily stored and transported cartons, boxes, and palettes.

Aseptic dairy processing & filling

Demand for aseptic processing and packaging is growing in the dairy industry. This process requires UHT pasteurization and aseptic conditions throughout the entire process. It is used to produce shelf-stable products for long-term storage (e.g. shelf-stable fluid milk or military food supplies).

One of the main benefits is extended shelf life and decreased transport costs because many products with aseptic packaging do not require refrigeration.

Dairy processing: key considerations for the future

Automation

Automation in dairy plants plays an important role in food safety, equipment safety, and personnel safety, all while supporting repeatable and robust processes throughout batching, pasteurization, or CIP—a result that’s nearly impossible in manual operations.

Automated equipment can monitor tanks and systems to help ensure cleaning, set off sophisticated alarms to alert if a product is out of the temperature safety zone, and ensure systems aren’t overpressurized or at risk of rupture. This is important to food safety, and it helps ensure both equipment and personnel safety as well. New/recent generations of automated dairy processing equipment can even lock out the wrong ingredients.

Automation can happen at the level of a single testing protocol or piece of equipment, or it can span an entire facility, from receiving to packaging. Fully automated facilities may require just two or three operators in a department per shift, who oversee the process from a central control room.

The more a dairy processing plant implements automation, the more it can potentially save over time, including:

- Decreased labor costs – Fewer operators means lower employee costs.

- Improved throughput – The less “human interaction” involved in processing, the fewer shutdowns as a result of an error.

- Proactive maintenance – An automated, data-driven plant is better positioned to predict and prevent equipment performance issues, resulting in fewer unexpected interruptions.

- Product safety – An automated, repeatable process with minimal “human interaction” can improve product quality.

Flexibility

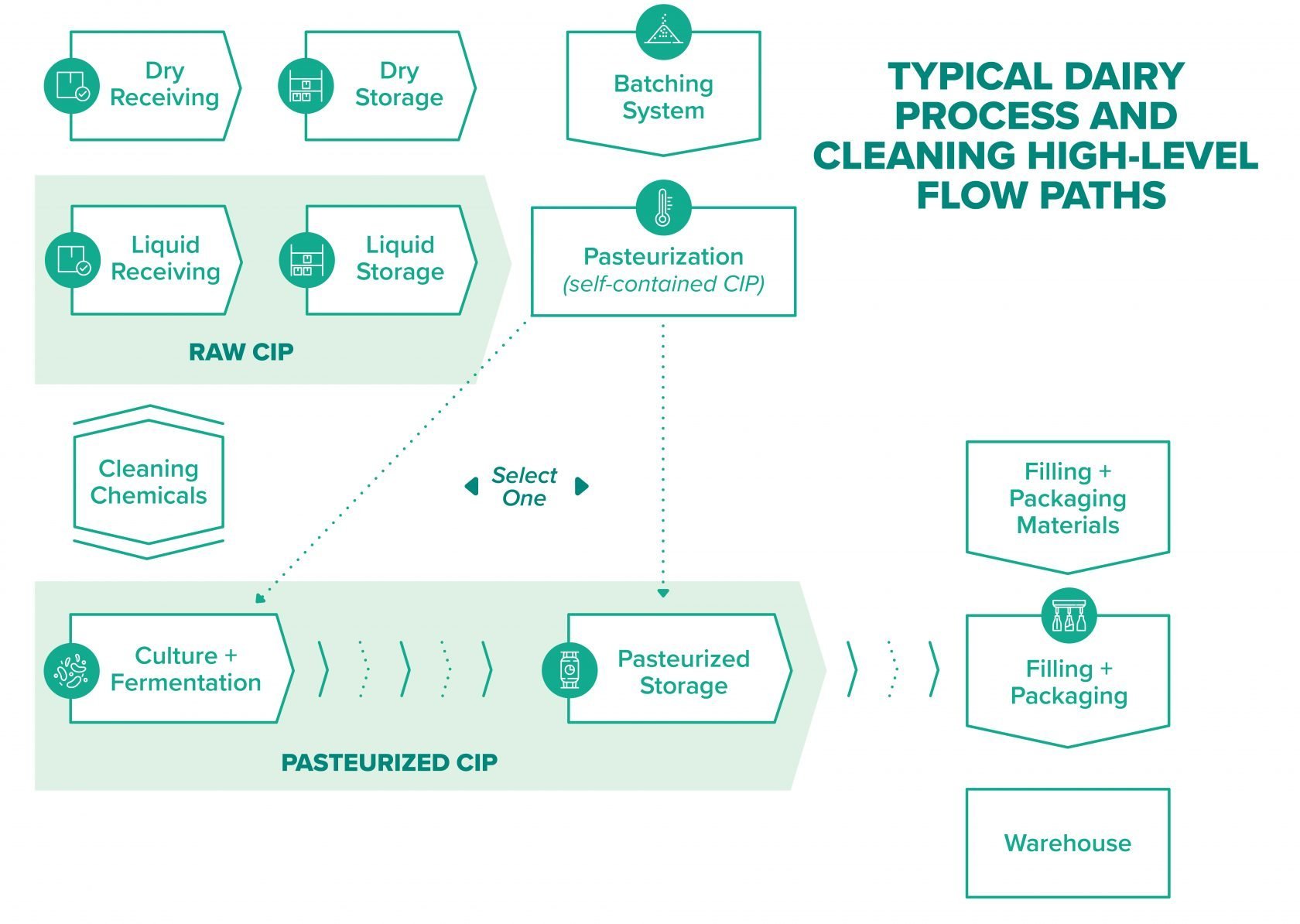

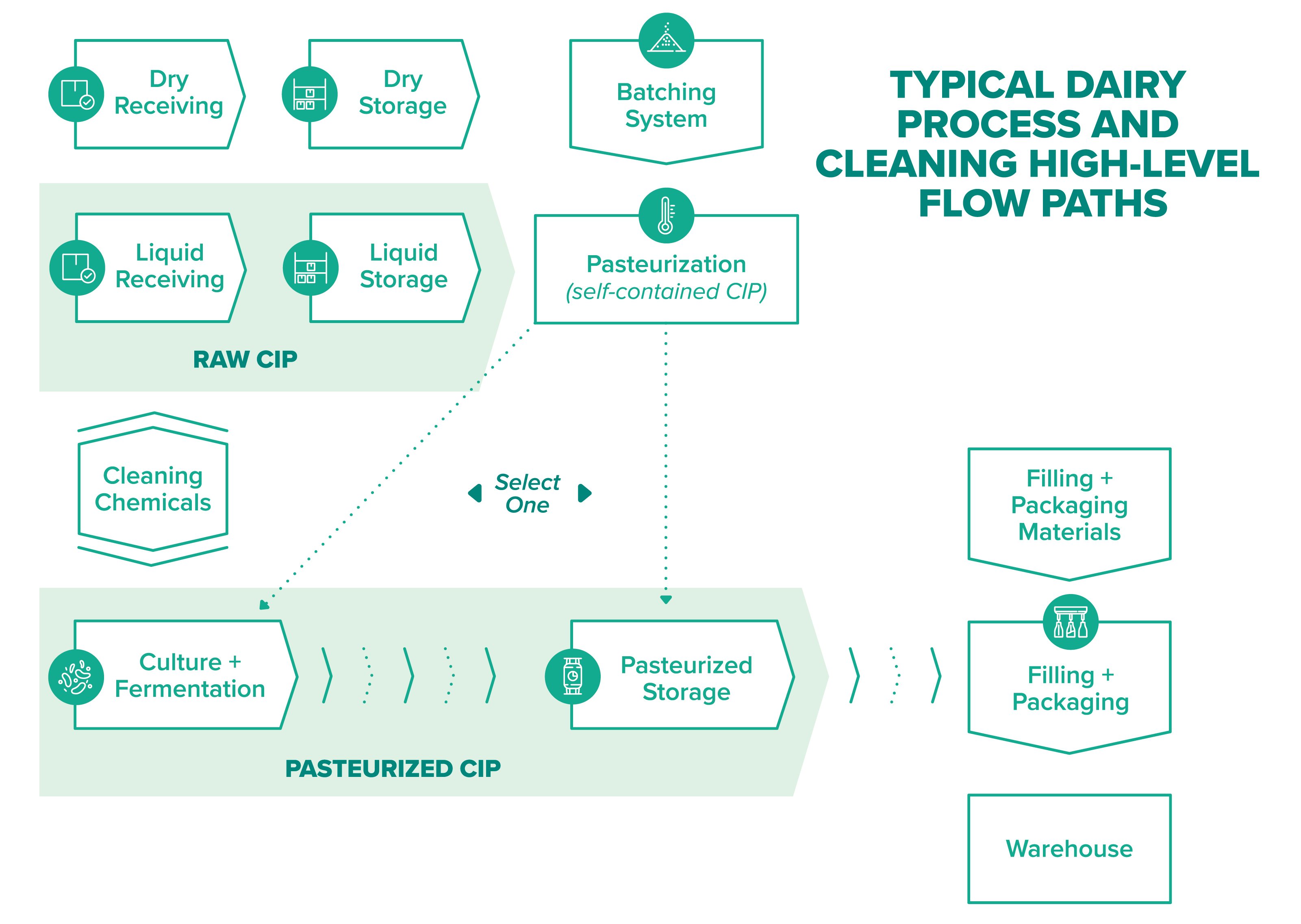

Increasingly, we see dairy producers looking for flexible, multi-product facility designs. This requires the right combination of parallel and concurrent activities to meet flexible processing demands through raw processing; pasteurization; culture and fermentation, as required; pasteurized storage; and filling and packaging. For example, a large facility might have multiple process systems feeding several dozen pasteurized storage tanks which in turn feed a dozen packaging lines, while also supporting simultaneous CIP operations, resulting in many possible combinations.

Of course, flexibility must be balanced with profitability. Large installers are not going to pause a highly profitable product run for a less profitable product on the same line. Similarly, they will likely not be keen to invest a large amount of capital to build a new line that doesn’t maximize profit.

Dairy processing plant design and construction

One enemy of any dairy plant is unwanted pathogens. Because dairy products are ideal breeding grounds for these unwanted invaders if not handled correctly, engineers must mitigate risk by following hygienic design principles. When it comes to pathogens, prevention is better than cure. Hygienic design principles guide both equipment and material selection and CIP processes to support food safety, as discussed below.

Equipment & material selection

Full draining is vital to hygienic design. When installing all pipes, tanks, and valves, facility planners must ensure that drains can be emptied completely. For example, there can be no ledges inside a tank that could prevent it from being fully drainable. Also, careful installation of hygienic valves ensures they function and drain optimally.

When selecting tanks and vessels for use within a dairy plant, facility planners should also consider several other hygienic factors:

- Avoid non-cleanable crevices (Minimum radius of a ⅛” for all inside corners and no 90-degree edges.)

- Assess and select agitator blades for their accessibility and cleanability.

- Ensure that the location, size, and length of tank top ports enable cleaning.

- Select tanks with dome tops so that CIP spray will create a cascade effect for full coverage.

Inappropriate materials in the processing environment allow corrosion and give pathogens the opportunity to evade sanitation activities, putting the product at risk of contamination. For example, the right grade of stainless steel can help prevent chlorinated caustic cleaners from forming pits inside the equipment.

Also, elastomers react differently to the fat content, temperatures, and other characteristics of any given product. For example, if an elastomer absorbs too much fat from a high-fat product, it can bloat and loosen—creating a potential breeding ground for pathogens. Selecting the right type of elastomer based on variables in the manufacturing process is key.

Sanitary design requires facilities to:

- Eliminate non-drainable traps

- Eliminate excessive dead legs

- Use tanks/pumps/valves conducive to automatic cleaning

Leverage CIP processes

In the past, operators cleaned dairy equipment manually. These activities required dismantling the piping systems and some equipment. Unfortunately, these cleaning tasks were inefficient and created opportunities to contaminate the system during the cleaning and reassembly steps, which led to quality issues and low shelf-life.

Industry pioneers developed Clean-In-Place (CIP) systems, design principles and CIP-cleanable equipment to meet the cleaning and sanitation needs of dairies. Other industries adopted and modified these principles to meet their needs, driving further innovation in how these systems are integrated and automated.

A CIP system cannot work optimally if non-drainable traps and/or excessive dead legs exist in a circuit. Excessive dead legs create cleaning issues because of reducing turbulence at points too far from the main flow path. Non-drainable traps create pools of retained liquids that can impact product quality over time. Careful equipment and system design can eliminate these concerns in an installation.

The most efficient way to help ensure a project design includes an effective and efficient CIP system is to design processes and CIP systems simultaneously and together. This approach helps maintain appropriate project budgets and schedules.

Food safety

An entire dairy plant must be constructed and maintained according to food safety protocols in order to keep the product within safe processing ranges. In addition to the design and installation describe above, there are several elements related to food safety including the handling of possible allergens, maintenance, and facility flow.

Allergens

Food safety takes on new meaning in multi-product facilities, where allergens become a risk factor. Facilities need to have a plan for addressing cross-contamination through either segregation or cleanability.

For example, consider a cream cheese processor with many SKUs. If one of those SKUs contains shellfish, specialized cleaning processes are necessary to prevent cross-contamination with any following SKUs.

Maintenance

Maintenance plays a huge role in the effectiveness of overall cleaning practices. Inattention can leave harborage points gaps or cracks where pathogens can grow unchecked and find their way into food products. Plant maintenance and sanitation teams must work diligently to maintain the sanitary design and fabrication throughout the lifetime of the facility. Following proper installation, thorough cleaning and regular maintenance are the keys to help ensure dairy facilities are clean and safe.

Facility Flow

The way that people, equipment and materials flow through the dairy plant can greatly impact food safety.

For example, before they deliver their load to the processing plant, raw receiving tankers—and, importantly, the people who drive them—pass through farms, where they are likely to contact and collect bacteria. Preventing these drivers from inadvertently contaminating the processing plant during a delivery comes down to two factors: sanitation and segregation.

Sanitation measures

Rigorous cleaning requirements between designated areas of the plant reduce the risk of contamination. These include:

- Boot wash stations

- Hand wash stations

- Uniform changes

Segregation measures

Sanitation measures help individual operators control their contamination risk, while a plant-wide segregation strategy goes even further, ensuring a physical separation between sensitive areas such as the raw processes, the pasteurizing processes, and the pasteurized processes. Segregation can be maintained through combinations of:

- HVAC systems

- Separate maintenance teams and tools for pre-kill and post-kill

- Color-coded cleaning equipment (e.g. drains, pre-kill, and post-kill)

- Limited access through key fobs

- Separate break rooms for truck drivers

- Closed processing (e.g. filling under aseptic conditions)

The future of dairy processing

Long-range planning calls for an understanding of both current and future business goals and how to effectively achieve them. Designing a facility that serves current needs with an eye to the future helps to ensure a sustainable return on your capital investment.

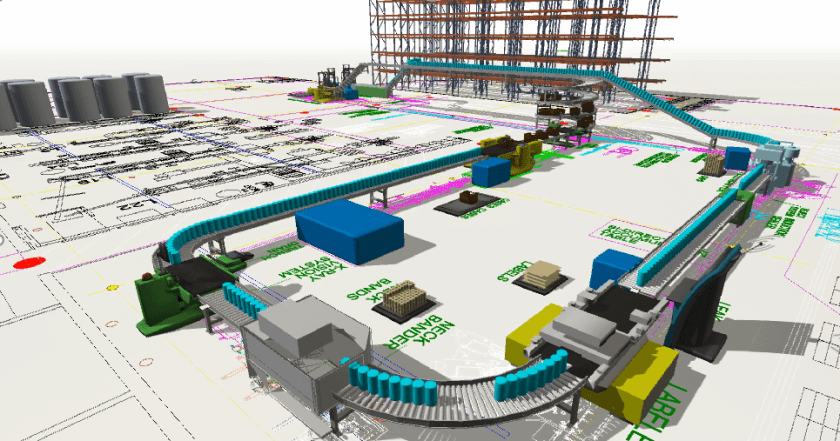

Simulating potential improvements in a process simulation model can help you test out strategies or find new opportunities.

One game changer in facility planning is process simulation. Although it’s been around for decades, interest in this field is burgeoning as more facility planners recognize its potential to save money and avoid costly planning errors.

Process simulation is exceptionally useful when sizing and quantifying equipment. For example, consider a company replacing aged storage tanks. By building a model of the plant environment and running simulations through that model, facility planners can test different variables, assess the impact of future shifts in demand, and ultimately calculate the best size and number of new storage tanks required. Facility owners can also see the impact on production if one or more tanks break down and plan for redundancy.

Some dairy facilities have gained a competitive edge by building long-term relationships with a specialized design and construction team, who can help them to plan for the future through strategic facility planning—an efficient alternative to a more reactive or piecemeal planning approach.

Are you ready for the future of dairy processing?

At CRB, we work closely with clients to understand their business goals and to help them meet those goals through a combination of the best technologies, design principles, and strategizing for the future. If you’re ready to step into the future of dairy processing, we’re here to help.